Project Description

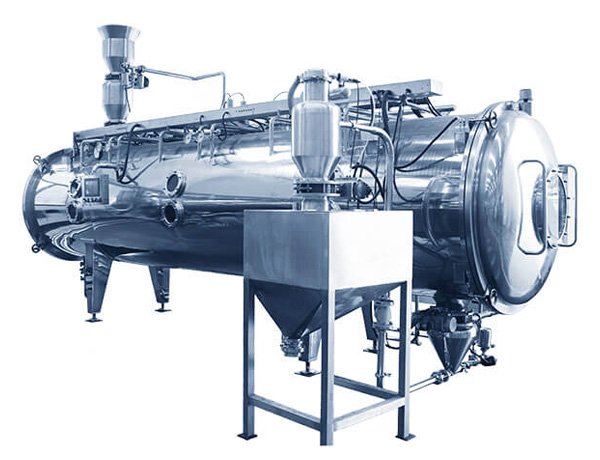

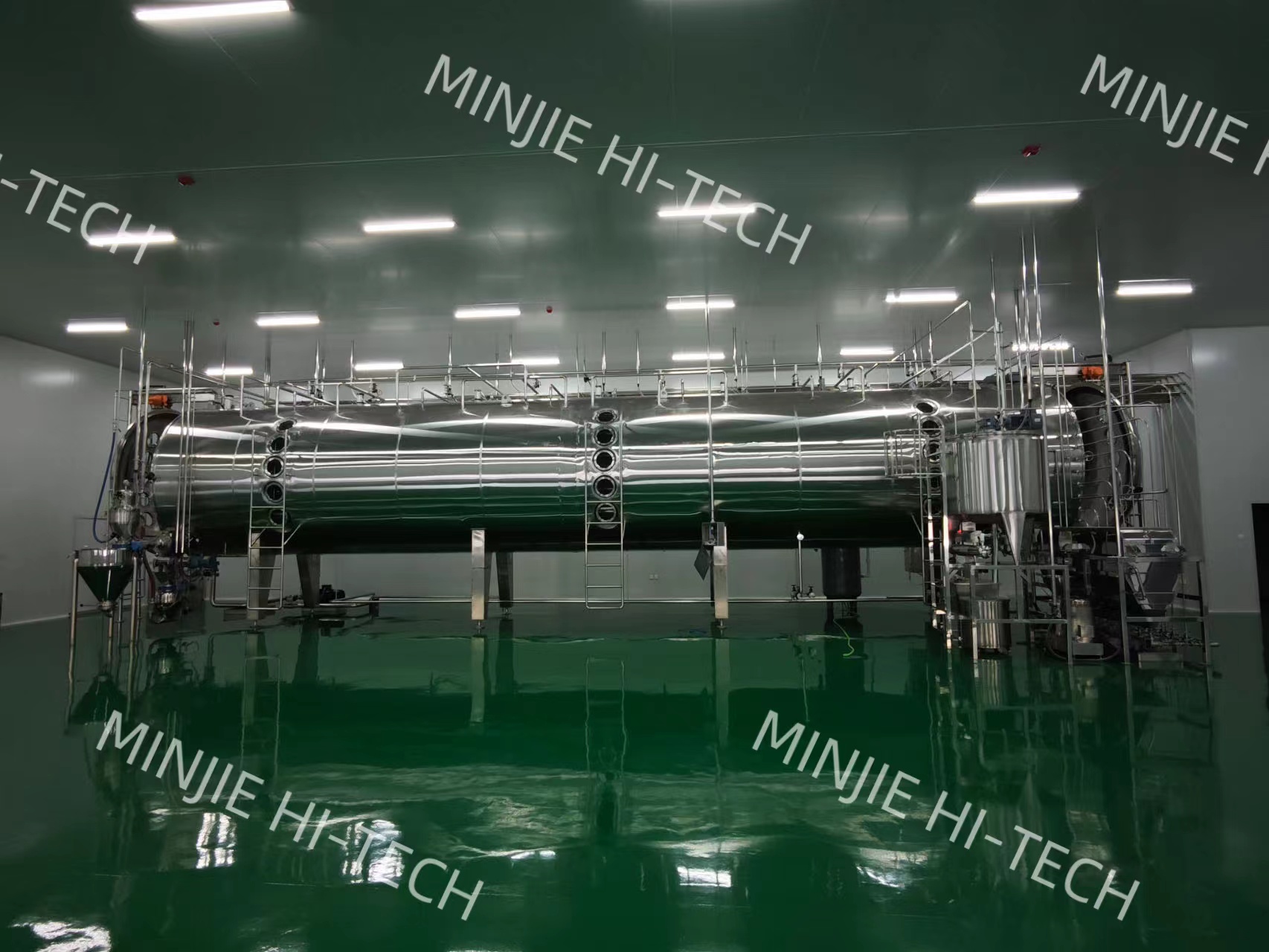

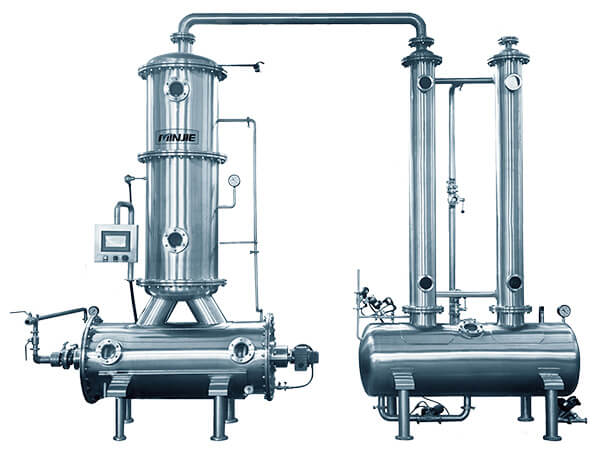

Vacuum Low Temperature Evaporator

Vacuum Concentrator Low Temperature Evaporator for Thin and Heat-sensitive liquid material

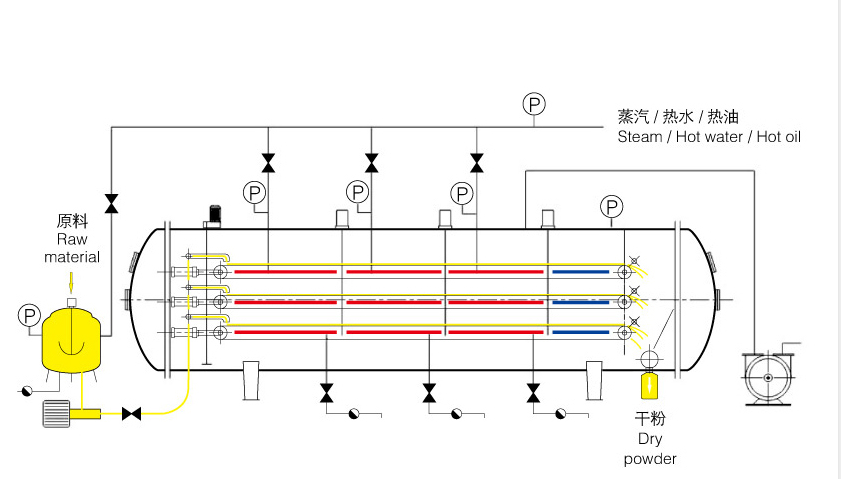

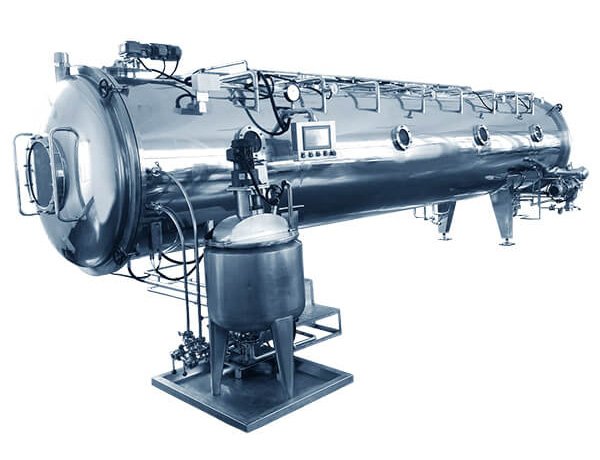

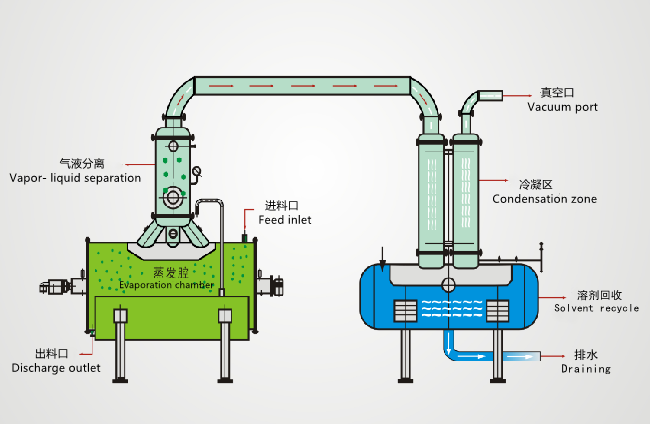

Vacuum low temperature evaporator is new concentrating equipment developed by our company. It realizes low temperature evaporation through high vacuum degree. There is a spinning roller inside the evaporator. Hot water is used to heat the bottom of the evaporator and the spinning roller. Continuous spinning of the roller increases evaporation area and speed, resulting in thin film evaporation. By continuous contact with the surface of the spinning roller, the raw thin material is heated to evaporate.

From feed to discharge, the whole concentration process is continuous under vacuum state. Vacuum low temperature evaporator conquers many problems met by traditional evaporator, such as, high concentrating temperature, long concentrating time, denaturation of raw material, easy scale formation during concentration, poor fluidity after concentration and no further concentration. Because of the low evaporation temperature in our equipment, active ingredients of the raw material are kept.

Vacuum Low Temperature Evaporator Video:

Advantage:

▪ Continuous feed in and discharge under vacuum state

▪ Automatic, continuous, closed process

▪ Protection of active ingredients of raw material under low temperature

▪ Adjustable concentration temperature (20-50°C)

▪ No limitation of density, as long as with fluidity

▪ Online density monitor, automatic discharge of finished material

▪ CIP system: quick & thorough cleaning, no dead corner

▪ Solvents recycling

▪ GMP Standards

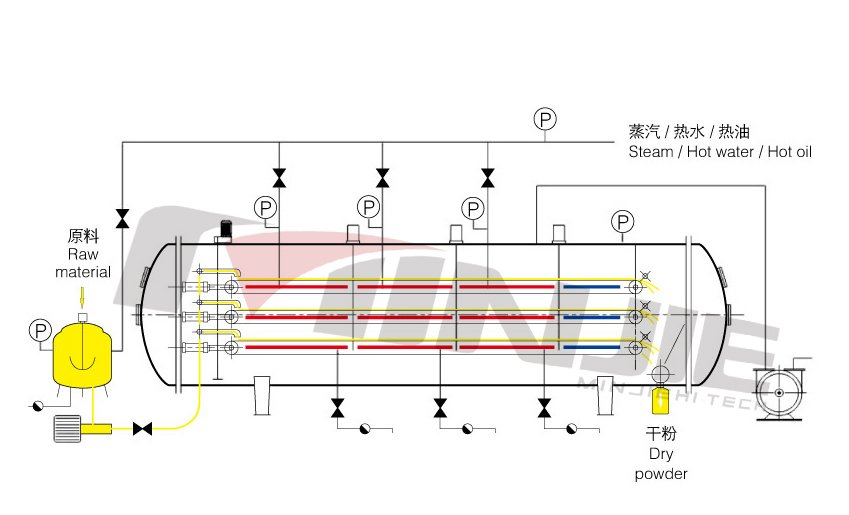

Vacuum Low Temperature Evaporator Work Flow :

Equipment Specification :

| Model | Heating area | Evaporation

capacity |

Vacuum degree | Heating

media |

Evaporation

temperature |

Density before

concentration |

Main dryer power | Weight | Outline

dimension |

| ㎡ | kg/h | MPa | ℃ | kw | kg | m | |||

| MJ-NS-3 | 3 | 60-100 | -0.098 | Hot water | 20-50

Adjustable |

With fluidity, density not

restricted |

3.9 | 1500 | 3.8×1×3.6 |

| MJ-NS-5 | 5 | 150-200 | 5.2 | 2200 | 5.2×1×4.2 | ||||

| MJ-NS-10 | 10 | 300-400 | 6 | 3000 | 6.5×1.2×4.2 | ||||

| MJ-NS-15 | 15 | 500-600 | 8.5 | 3800 | 6.5×1.2×4.5 | ||||

| MJ-NS-20 | 20 | 600-800 | 11 | 5000 | 6.5×1.4×4.6 |

The power consumption listed above do not include the vacuum units、water chilling unit、hot water pump.

— WHY CHOOSE MINJIE —

A company specialized in research, manufacturing, sales of pharmaceutical, foodstuff, chemical and biotechnology machinery.

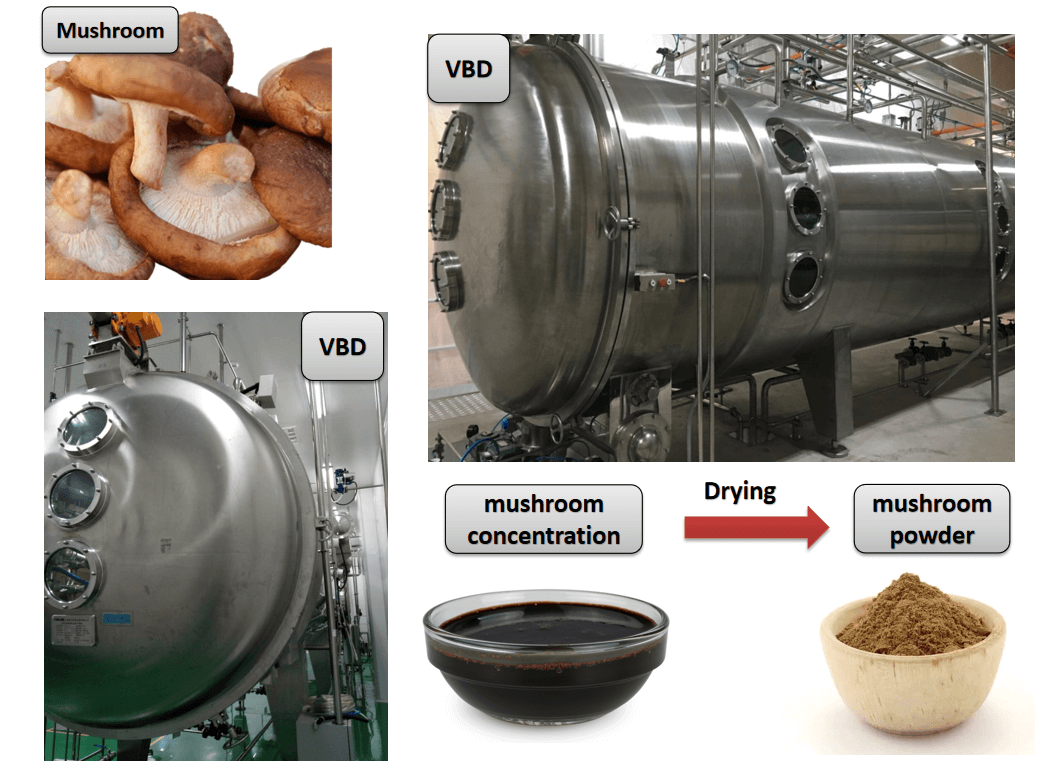

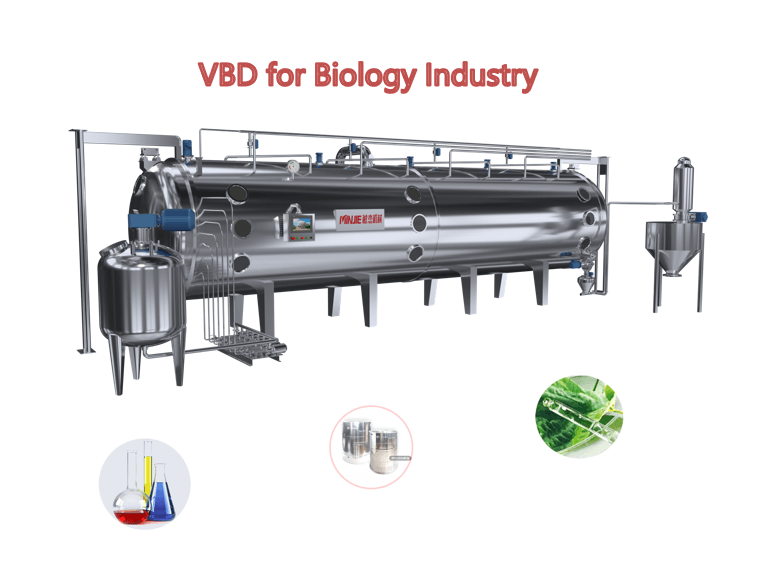

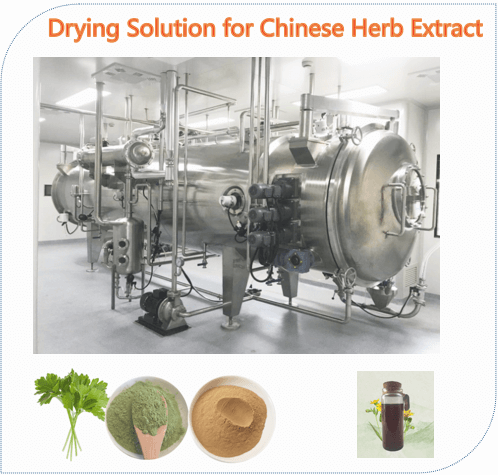

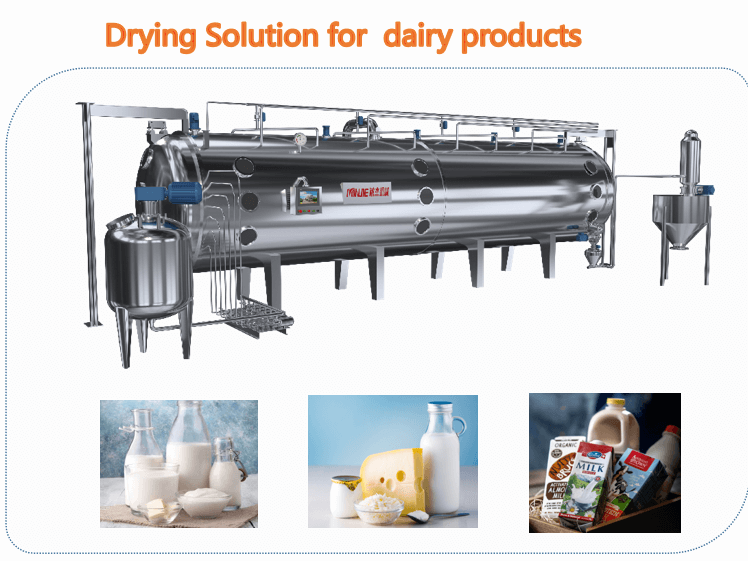

- The first factory in China to produce Vacuum Belt Dryer(VBD)

- Developed the first set of Energy-saving Evaporator in China

- 20 years experience in VBD and Evaporator Solution production line

- Rich experience in overseas export and service (over 500 cooperative partners)

- Win large market (over 700 sets Minjie series VBD around the world)

- Supply ability is more than 100 sets VBD per year

- Has a professional technical R&D team,specialized in researching and developing advanced evaporator and drying equipment

- Own many patents and authentication certificates for VBD and Evaporator

- Excellent quality of the products

- GMP standards

- Technical support After-sales Service Provided (Installation instructions, Commissioning, Training)

FAQ

Answer: Minjie engages in research, manufacturing and sales of advanced drying equipment (vacuum belt dryer & thin-layer drying system), low temperature vacuum evaporator and sterilization equipment.

Answer: It is the strength of R&D, the highness of technique, and the standardization of production that synthetically ensures steady quality of Minjie equipment.

Answer: 1 set.

Answer: Consultation, test, technical scheme determination, business negotiation, contract.

Answer: Steam, industrial electricity, water, compressed air.

Answer: CIP cleaning system, automatically and continuously.

Answer: 24-hour service hotline is available. Engineers onsite to guide installation, commissioning and training.

Answer: 1 year after finishing installation and commissioning.