Material description:

Known as the king of protein, whey protein is a protein extracted from milk. It has the characteristics of high nutritional value, easy digestion and absorption, and contains a variety of active ingredients. It is recognized as one of the high-quality protein supplements for the human body.

Whey protein refers to the protein dissolved and dispersed in the whey, accounting for about 18% to 20% of the milk protein. It can be divided into two parts: heat stable and heat unstable whey protein.

When whey liquid is boiled for 20 minutes at pH=4.6~4.7, the type of protein that precipitates is heat-labile whey protein, mainly including lactalbumin and lactoglobulin; the protein that does not precipitate is heat-stable protein This type of protein accounts for about 19% of whey protein.

When saturated ammonium sulfate or saturated magnesium sulfate is added to neutral whey to precipitate out, the protein that is in a dissolved state without precipitation is lactalbumin, and the protein that can be precipitated without being dissolved is lactoglobulin.

So how does whey protein dry into powder? This requires a whey protein vacuum dryer produced by Shanghai Minjie Machinery.

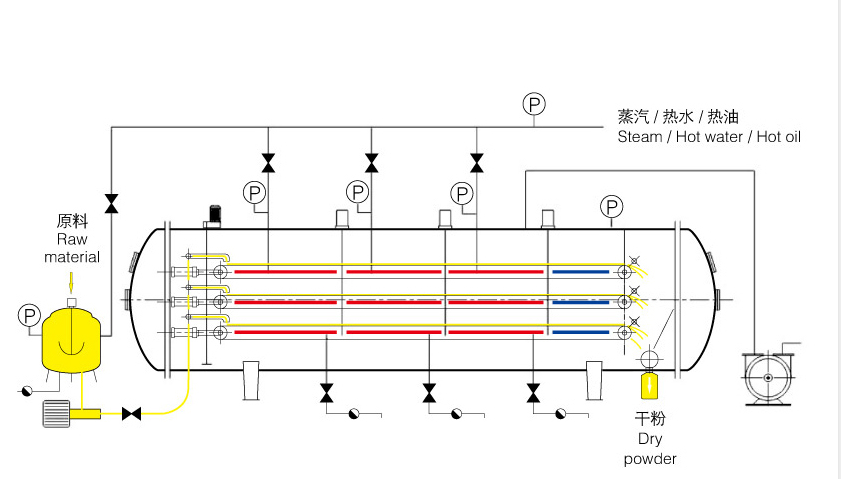

The whey protein raw material is transported to the dryer through the feed pump, and is evenly distributed on the conveyor belt through the distributor. The boiling point temperature of the material is reduced through high vacuum. The moisture of the liquid raw material is directly sublimated into gas, and the conveyor belt runs at a uniform speed on the heating plate. The heat source in the heating plate can be steam, hot water or electric heating. Through the operation of the conveyor belt, the material is discharged from the evaporation and drying at the front end to the cooling discharge at the back end. The temperature range is from high to low, and the material is adjusted according to the characteristics of the material. The end is equipped with a specific vacuum crushing device to reach the finished products of different particle sizes, and the dried powder can be automatically packaged or subsequent processes.

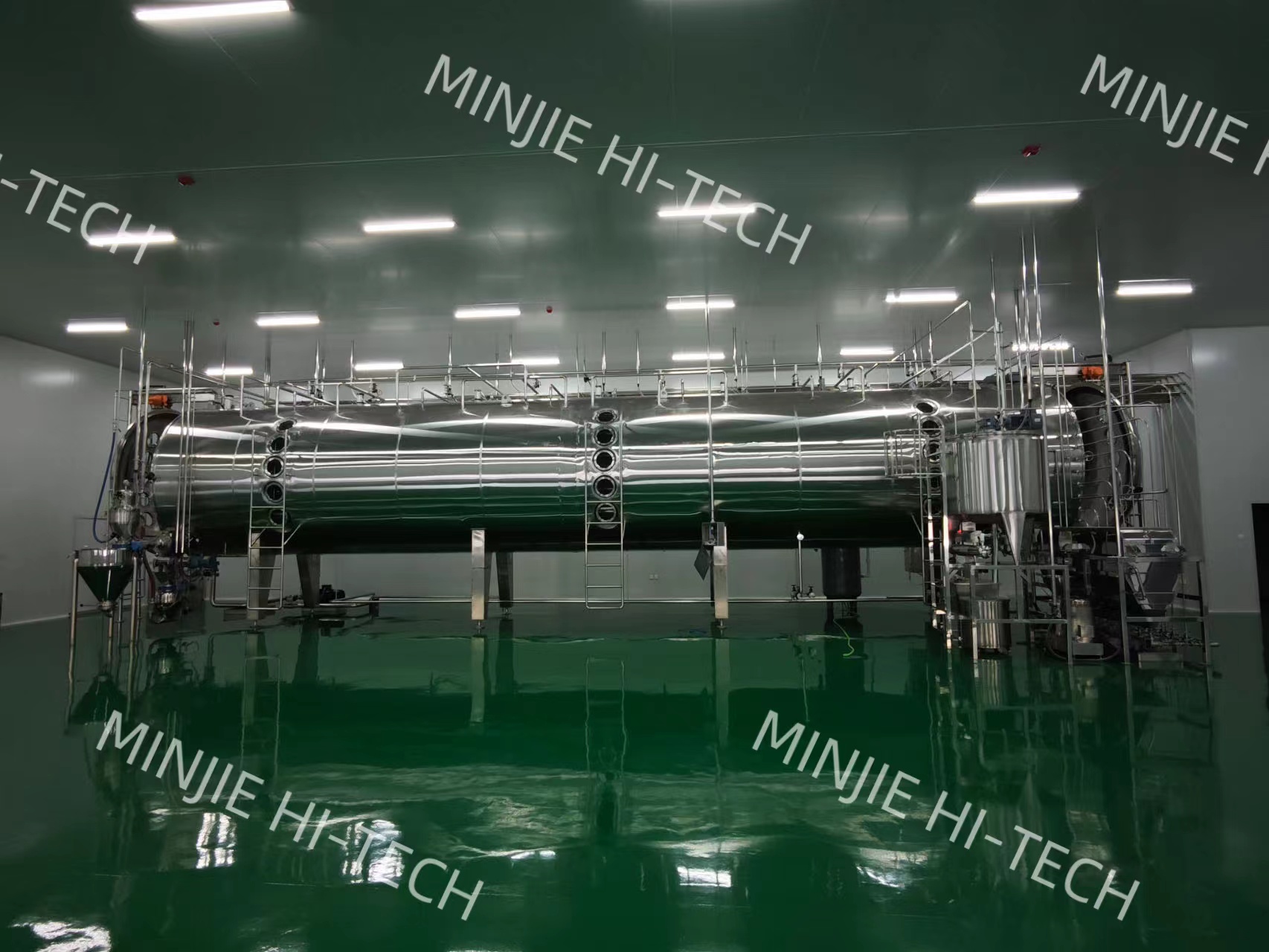

The whey protein vacuum dryer has the characteristics of a complete set of process automation, pipelineization, and continuity. It only needs 1-2 people to operate. Save labor costs for our customers. Because our equipment is a vacuum and low temperature environment, the color and solubility of the dried product are unmatched by other equipment, and the dry powder output rate is 99%.

Flow chart of whey protein vacuum dryer:

Technical parameters of whey protein vacuum dryer:

| Model | Diameter | Length | Height | Heating area | Heating temperature | Moisture content of feeding material | Moisture content of dried product | Heating resource |

Water Evaporation | Dryer body power |

| mm | mm | mm | ㎡ | ℃ | % | % | kg/h | kw | ||

| MJY30-4 | 1700 | 9800 | 2700 | 30 | 30-150 | 20-80 | 0.2-5 | Steam/Hot water /Oil | 15-25 | 10 |

| MJY60-6 | 2200 | 10800 | 3650 | 60 | 45-55 | 14 | ||||

| MJY80-6 | 2200 | 13500 | 3650 | 80 | 60-75 | 14.5 | ||||

| MJY100-6 | 2200 | 16100 | 3650 | 100 | 80-90 | 15.5 | ||||

| MJY120-7 | 2200 | 16100 | 3650 | 120 | 100-110 | 16.5 | ||||

| MJY160-8 | 2800 | 17300 | 4100 | 160 | 120-140 | 18.5 | ||||

| MJY200-10 | 2800 | 17300 | 4150 | 200 | 160-180 | 25.5 |