Functional Sugar Application

Functional sugar is now widely used in Food and Beverage,nutrition, bakery and snacks, dairy and other industries.

They also have great benefits over human health as they can provide certain needed nutrition.

Among them Low-Calorie Sweetener is a leading trend now, as it helps to prevent extra calorie intake, thus keeping a more slim and healthy body.

With the development of society,functional sugars are more and more common in daily life,thus there is great demand for functional sugar.

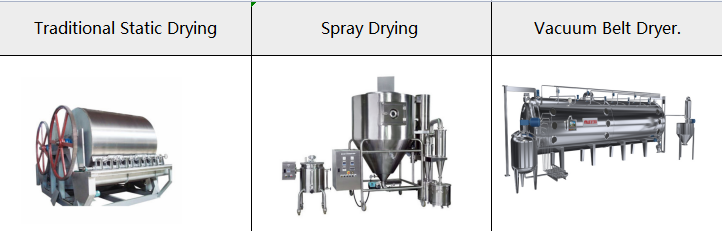

Most common 3 types of common drying equipment

Usually, there are 3 typical ways to dry functional sugar.

- traditional static drying,

- spray drying

- new-style vacuum continuous drying machine, also called a vacuum belt dryer.

Having a better understanding of the characteristics of these three drying equipment will help you choose the best suitable machine for you. Now let’s talk about how to choose the right function sugar dryer.

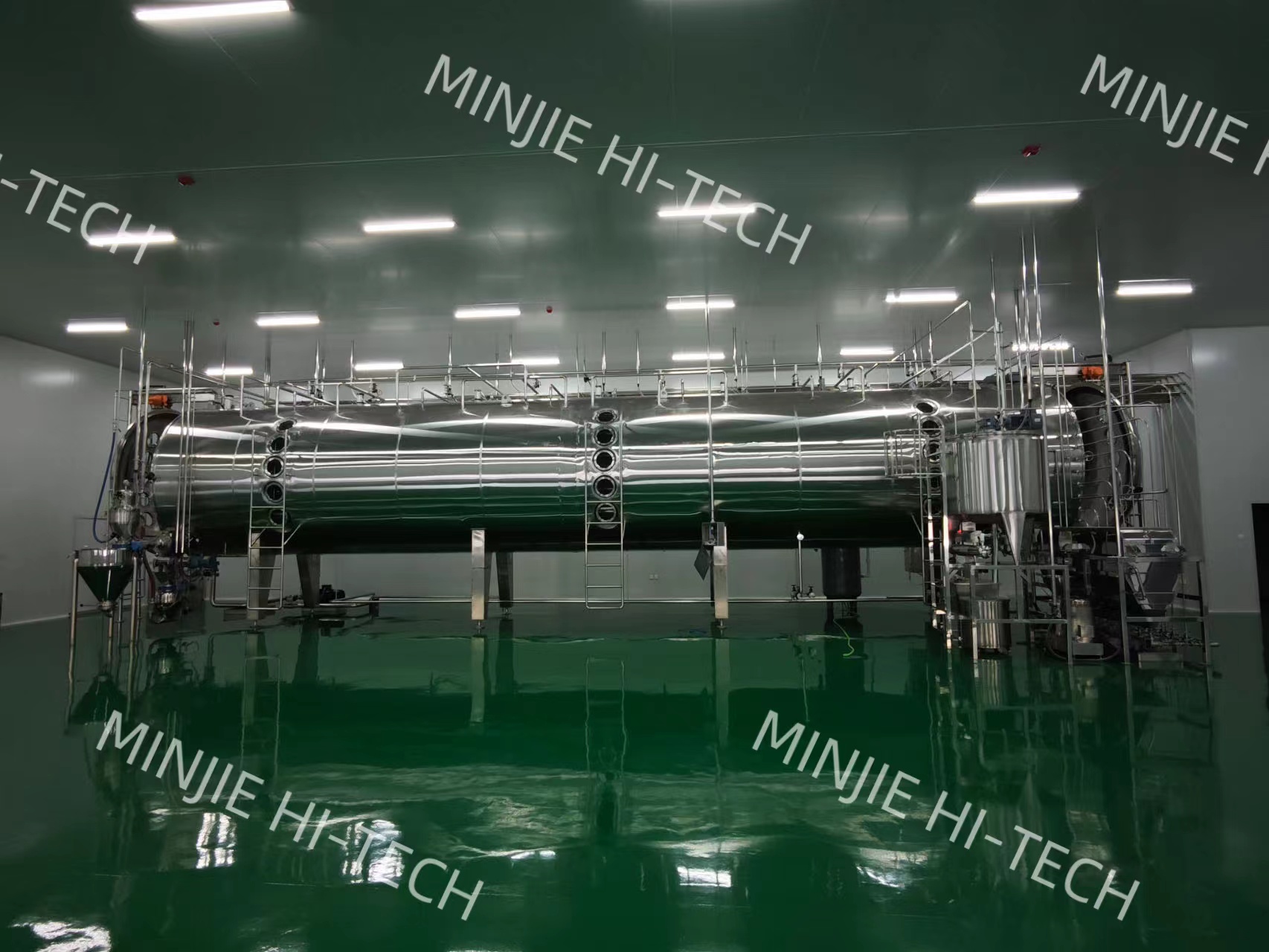

How is vacuum belt dryer be developed?

A few years ago, the vacuum drying machine used in function sugar drying was usually made by static vacuum drying, by but by this method, the drying process could not be continuous , thus the whole process was very complex, so the static drying was not ideal.

Later, the static drying equipment was gradually replaced by spray dryer. Compared with the traditional static drying equipment, the spray dryer has a great advantage in drying speed, and the production process is simplified and the operation control is relatively convenient.

However, spray drying requires relatively high separation of atomized materials, especially solid and gas mixtures, and requires at least two stages of dust removal,and the thermal efficiency is low.Especially when the air temperature is lower than 150 ℃, the volumetric heat transfer coefficient is low ,so the corresponding equipment volume reuired is much large.Also, when sugar is dried in a spray dryer, it is easily stick to the dryer shell, causing blockage and material waste.

For these reasons,Shanghai Minjie invented a newly continuous vacuum dryer for sugar drying. Unlike the spray dryer that needs not be dismantled when cleaning residual substances. The vacuum low-temperature continuous dryer realizes automatic cleaning, saves a lot of time and labor cost, and there is no need to worry about dust removal under vacuum.

In conclusion, when considering the drying efficiency,end-product quality and energy-saving , labor saving, a continuous vacuum belt dryer would be the best choice.