Project Description

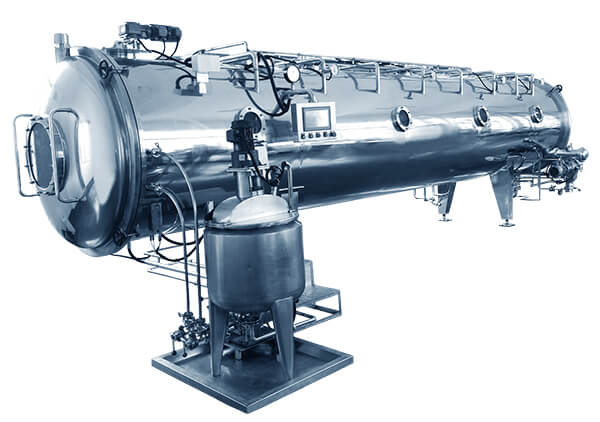

Vacuum Belt Dryer For Liquid & Paste

Continuous vacuum belt dryer for efficient, gentle drying of concentrates

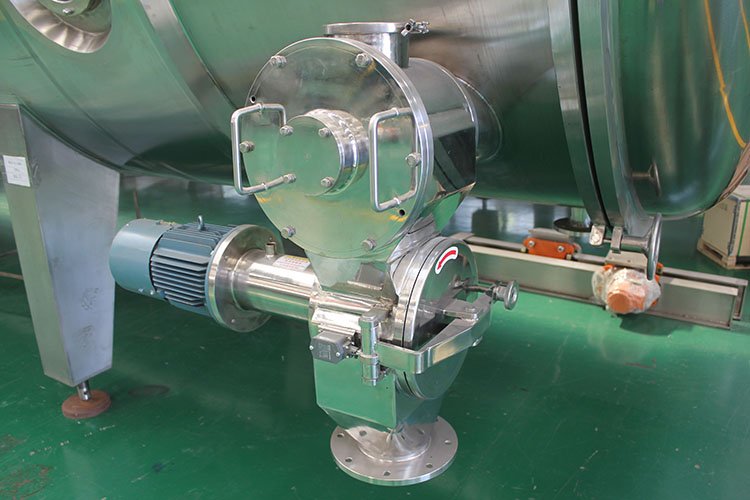

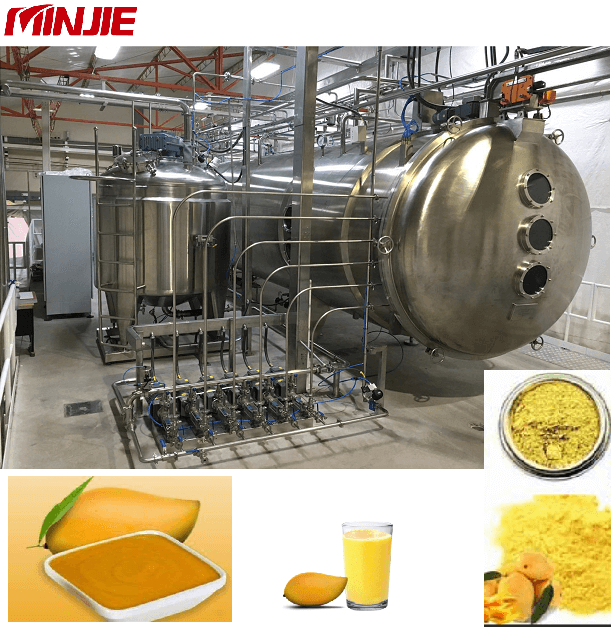

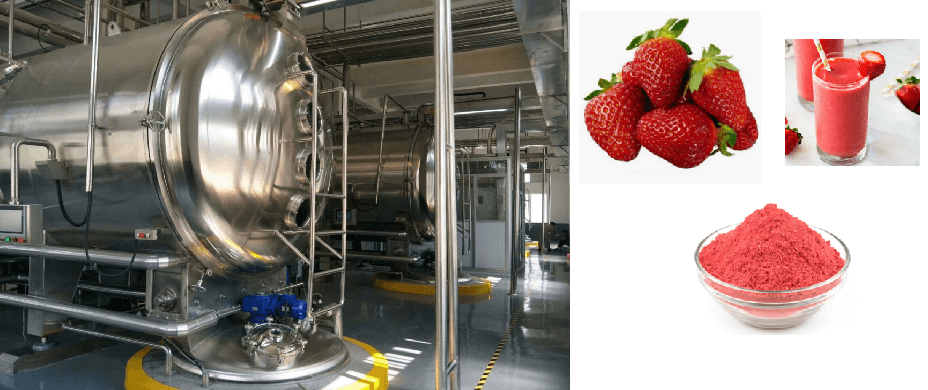

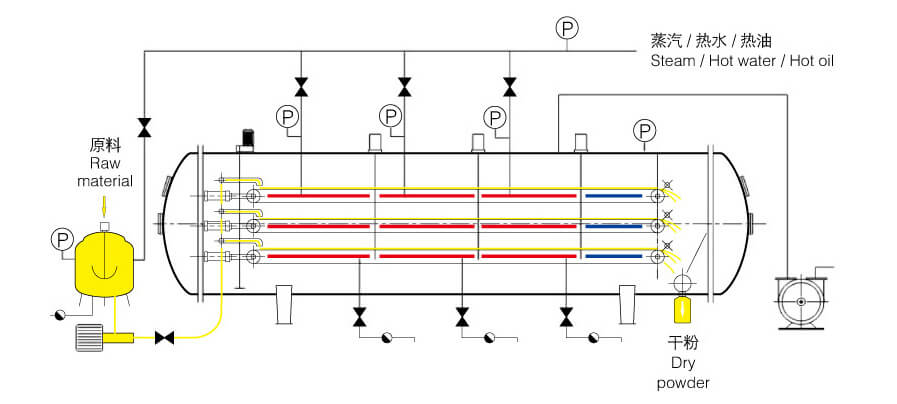

Vacuum belt dryer is continuous infeed and discharge vacuum drying equipment. Liquid product is conveyed into dryer body by infeed pump, evenly spread on belts by distribution device. Under high vacuum, the boiling point of the liquid is lowered; water in the liquid material is evaporated. Belts move on the heating plates evenly. Steam, hot water, hot oil can be used as heating media. With the moving of the belts, the product goes through from the beginning evaporating, drying, and cooling to discharging in the end. The temperature decreases through this process, and can be adjusted for different products. Special vacuum crusher is equipped at the discharge end to produce different size end product. The dry powder or granule product can be automatically packed or continue with subsequent process.

Vacuum belt dryer turn traditional static drying to vacuum dynamic drying, reduce drying time from 10-20 hours to 30-60 minutes. In vacuum belt dryer, the drying temperature is adjustable for different products. It solves the high temperature problem with spray dryer and denaturation problem due to long drying time with traditional drying oven. Colors, solubility, ingredients preservation of the dry product from vacuum belt dryer are incomparable.

Vacuum Belt Dryer Videos :

Advantage:

▪ Bespoke engineered continuous drying solution to fit your requirements

▪ Continuous and gentle drying preserving maximum colour, flavour and composition, and minimal oxidation

▪ Individual temperature zones allow for product-specific profiles to be developed suited to each perfectly to each product

▪ Less energy used than other drying methods

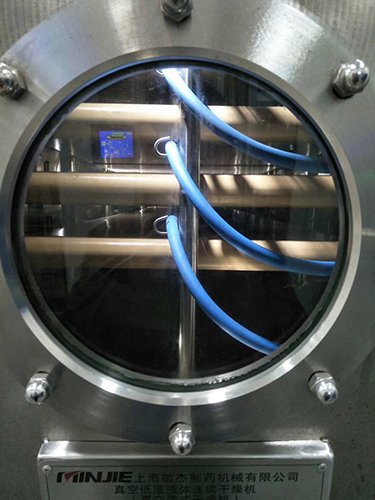

▪ Viewing windows as standard allow for continuous monitoring, with options for automated monitoring systems available

▪ Product specific feeding and discharging systems

▪ Fully PLC automated operation & CIP cleaning system

▪ GMP standards

Vacuum Belt Dryer Work Flow :

Equipment Specification

| Model | Diameter | Length | Height | Heating area | Heating temperature | Moisture content of feeding material | Moisture content of dried product | Heating

resource |

Water Evaporation | Dryer body

power |

| mm | mm | mm | ㎡ | ℃ | % | % | kg/h | kw | ||

| MJY30-4 | 1700 | 9800 | 2700 | 30 | 30-150 | 20-80 | 0.2-5 | Steam or Hot water or

Hot oil |

15-25 | 10.00 |

| MJY60-6 | 2200 | 10800 | 3650 | 60 | 45-55 | 14.00 | ||||

| MJY80-6 | 2200 | 13500 | 3650 | 80 | 60-75 | 14.50 | ||||

| MJY100-6 | 2200 | 16100 | 3650 | 100 | 80-90 | 15.50 | ||||

| MJY120-7 | 2200 | 16100 | 3650 | 120 | 100-110 | 16.50 | ||||

| MJY160-8 | 2800 | 17300 | 4100 | 160 | 120-140 | 18.50 | ||||

| MJY200-10 | 2800 | 17300 | 4150 | 200 | 160-180 | 25.50 |

If the solvent of raw material is organic (ethanol, acetone, methanol etc.),evaporation capacity would rise. Evaporation capacity is closely related with drying temperature.

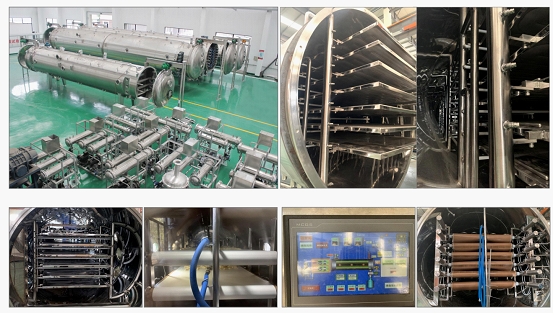

Production Process :

1. Raw materials

2. Parts Processing

3. Welding

4. Polishing

5. Parts assembling

6. Casting polishing

7. Assembling

8. Inspection

9. Electrical control cabinet assembling commissioning inspecting

10. Pneumatic control cabinet assembling commissioning inspecting

11. Stocking

— WHY CHOOSE MINJIE —

A company specialized in research, manufacturing, sales of pharmaceutical, foodstuff, chemical and biotechnology machinery.

- The first factory in China to produce Vacuum Belt Dryer(VBD)

- Developed the first set of Energy-saving Evaporator in China

- 20 years experience in VBD and Evaporator Solution production line

- Rich experience in overseas export and service (over 500 cooperative partners)

- Win large market (over 700 sets Minjie series VBD around the world)

- Supply ability is more than 100 sets VBD per year

- Has a professional technical R&D team,specialized in researching and developing advanced evaporator and drying equipment

- Own many patents and authentication certificates for VBD and Evaporator

- Excellent quality of the products

- GMP standards

- Technical support After-sales Service Provided (Installation instructions, Commissioning, Training)

FAQ

Answer: Minjie engages in research, manufacturing and sales of advanced drying equipment (vacuum belt dryer & thin-layer drying system), low temperature vacuum evaporator and sterilization equipment.

Answer: It is the strength of R&D, the highness of technique, and the standardization of production that synthetically ensures steady quality of Minjie equipment.

Answer: 1 set.

Answer: Consultation, test, technical scheme determination, business negotiation, contract.

Answer: Steam, industrial electricity, water, compressed air.

Answer: CIP cleaning system, automatically and continuously.

Answer: 24-hour service hotline is available. Engineers onsite to guide installation, commissioning and training.

Answer: 1 year after finishing installation and commissioning.