Heat sensitive liquid materials require concentration at low temperature (20-50℃)

Fruit juice concentrate a large amount of water from the fruit juice after squeezing the fruit into the original juice. Although the nutritional value of fruit juice is not rich, it also contains a lot of dietary fiber and vitamin C, which can promote digestion and supplement part of the nutrients needed by the human body. It should be noted that the nutritional components of vitamins will decompose and deteriorate at high temperature, and the longer the heating time, the greater the loss. Therefore, juice concentration production needs to choose a process that can handle heat-sensitive materials and has a fast concentration efficiency.

Development of juice concentrate technology

The booming fruit juice industry can not only reduce the proportion of concentrate in the solution container, but also reduce storage and transportation costs due to the overall light weight. The industrial fruit juice industry relies on fully automated concentration equipment to achieve continuous, mass processing without the need for fruit storage equipment, which reduces the loss caused by fruit transportation. As an important unit operation of food processing, the main technologies include high temperature concentration, low temperature vacuum concentration, film concentration, etc.

Due to the loss of nutrients and changes of flavor substances caused by high temperature concentration technology in the production process, it is rarely used now. At present, the price of reverse osmosis technology is still high, and only some enterprises are using it, while low temperature vacuum concentration is the choice of most enterprises.

Principle of low temperature concentration technology of fruit juice

Low temperature vacuum concentration technology is a mature and widely used evaporation technology at present. It is not only widely used in food industry, but also in wastewater treatment and chemical raw materials extraction. The principle and structure of low-temperature vacuum technology is simple, and the main equipment includes evaporation chamber and vacuum pump. The principle of evaporation is that the lower the boiling point is when the pressure rises after the vacuum degree increases, the lower the boiling point is, the evaporation and vaporization reaction will still occur. The heat-sensitive materials of juice concentrate at low temperature, so that the nutrients can be retained without being destroyed.

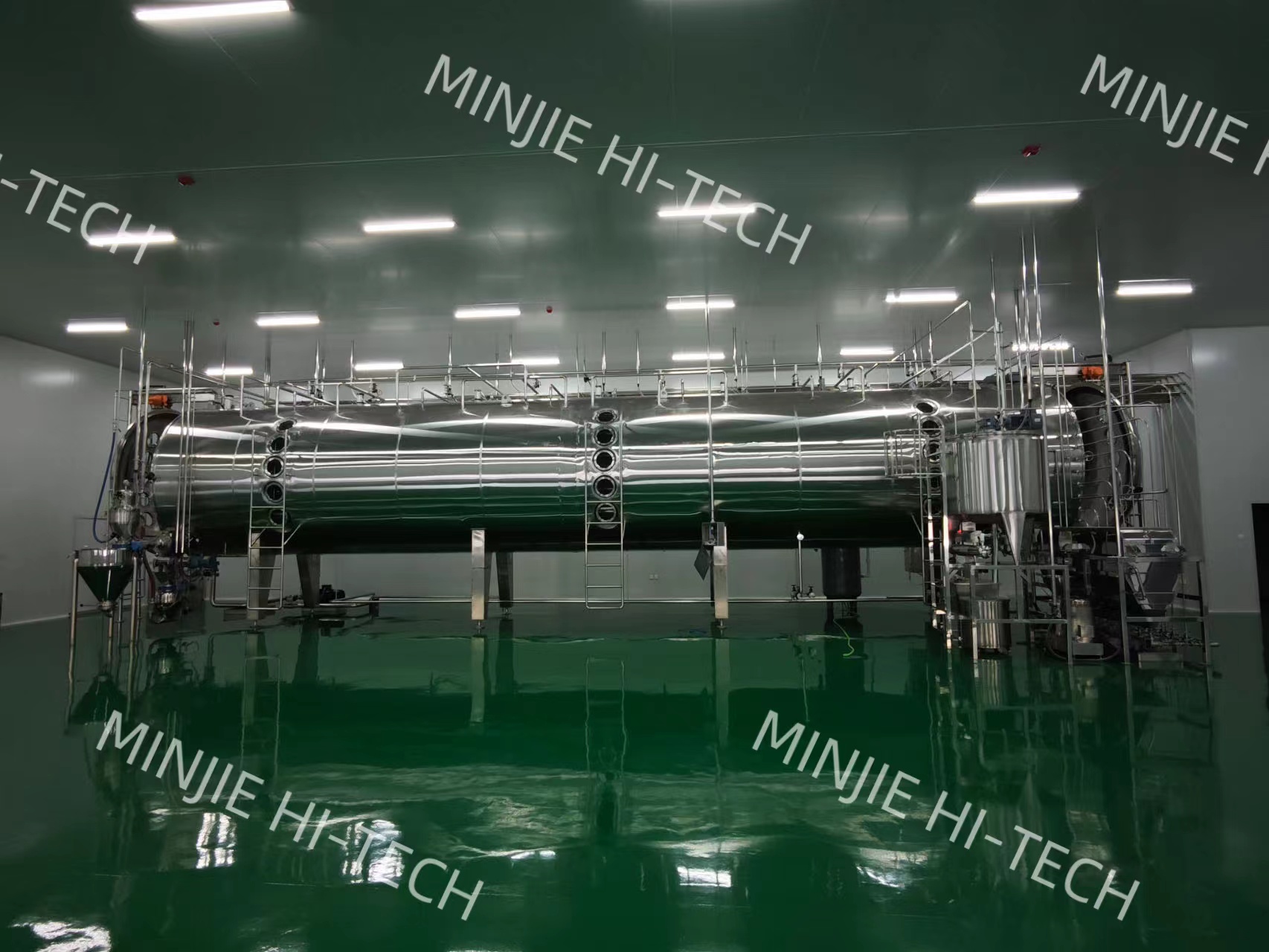

SHANGHAI MINJIE has become a leading manufacturer of Vacuum Belt Dryer & Evaporator since established in 1998.

For any enquiries, please contact: Caroline LI

Email address: globalsales1@shmjjx.com

Mob # /Whatsapp: +86 183-0190-2739