Project Description

Airflow Instaneously Heating Sterilizer

Airflow instaneously heating sterilizer for various powder & granule materials

Through three years’ effort, we successfully developed airflow instantaneously heating sterilizer, which solves powder & granule material’s sterilization process problems in traditional Chinese medicine, food & healthcare, and so on industries.

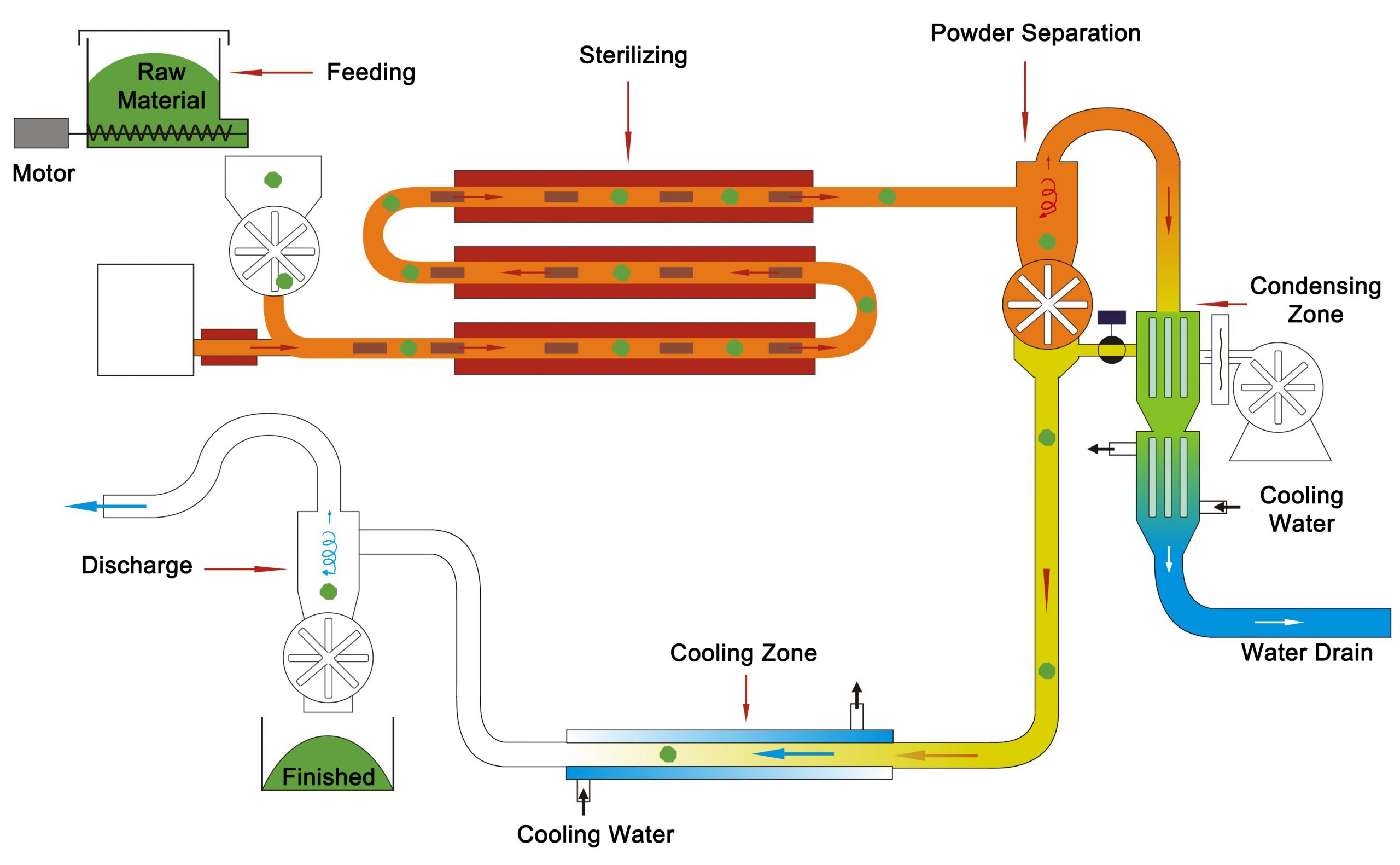

WORKING PRINCIPLE

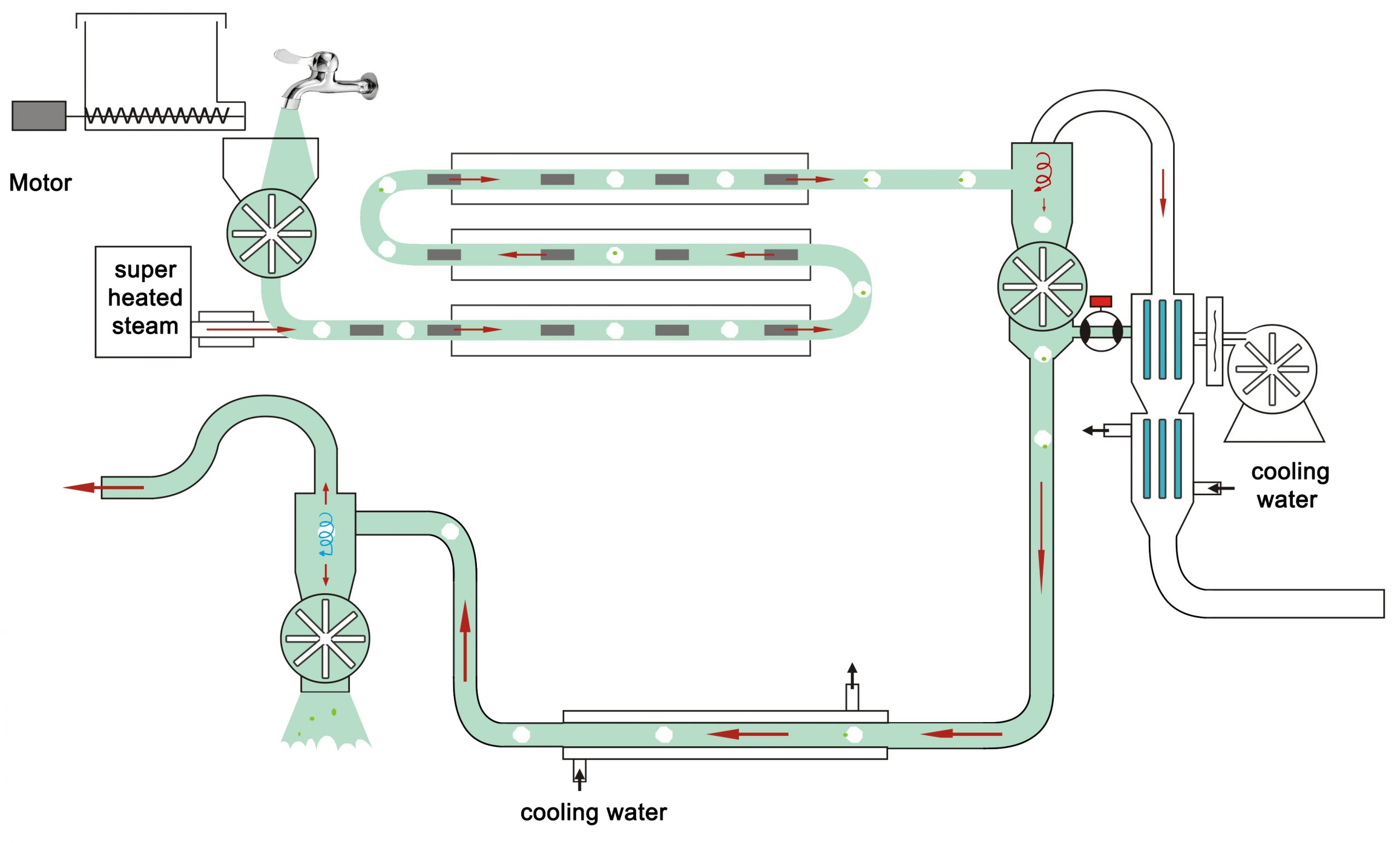

Adopting superheated steam as auxiliary heating media, raising the temperature of air to over180℃ , at the same time, powder and granule material be transported by steam pressure. The sterilizing process is finished in 4 seconds, then through vapor powder separation into cooling zone. After cooling, the material will be separated with air, then discharged.

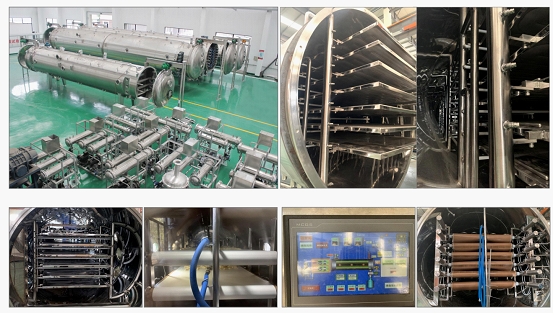

MAIN CONFIGURATION

Airflow instantaneously heating sterilizer consist of continuous feeding system, heating sterilization system, vapor & powder separating system, cooling system, continuous discharging system, automatic cleaning system, automatic controlling system.

EQUIPMENT ADVANTAGE

Simple & instantaneous sterilization process, no residue, the loss rate of effective component is lower than 2%, sterilization indicator- the total number of biological bacteria per gram is less than 300. Due to pressure, temperature and every treatment condition can be freely adjusted, so the sterilization application is very wide, can be applied to various powder & granule material’s sterilization.

STERILIZATION TEST DATA:

| Material name | before sterilization treatment | after sterilization treatment | |||

| number of bacteria | Number of coliform bacteria | number of bacteria | Number of coliform bacteria | ||

| cfu/gm | cfu/g | cfu/g | Positive/ negative | ||

| leaf & roots | |||||

| Barley leaf | 7.5×104 | 1.3×102 | <300 | negative | |

| Matcha | 3.0×103 | 5.6×102 | <300 | negative | |

| Taiwan jute | 7.0×104 | positive | <300 | negative | |

| Cereals legumes | |||||

| rice powder | 1.0×104 | negative | <300 | negative | |

| Rice Bran | 1.5×106 | negative | <300 | negative | |

| Soybean | 1.0×104 | negative | <300 | negative | |

| Mushrooms | |||||

| Hericium erinaceus | 1.0×104 | negative | <300 | negative | |

| root &vegetable | |||||

| ginger | 1.0×103-5 | positive | <300 | negative | |

| Maca | 9.0×104 | 1.5×10 | <300 | negative | |

| seaweed | |||||

| Ulva lactuca L | 7.8×103 | negative | <300 | negative | |

| spirulina | 5.0×104 | negative | <300 | negative | |

| Fish | |||||

| bonito stick powder | 2.0×104 | negative | <300 | negative | |

| bonito stick granule | 2.7×105 | negative | <300 | negative | |

SPECIFICATIONS

| Model | MJMJ-50 | MJMJ-100 | MJMJ-200 | MJMJ-300 | MJMJ-500 | ||

| Main material | SS304 | ||||||

| Main machineSize | mm | 3200×2000×2600 | 3400×2400×2600 | 3680×2480×2800 | 4000×2600×3200 | 4200×2800×3200 | |

| Weight | T | 2 | 2.5 | 3.5 | 4 | 4.5 | |

| Real consumption | Power source | kw | 20 | 30 | 40 | 50 | 65 |

| Steam | ㎏/hr | 125 | 200 | 350 | 500 | 800 | |

| Compressed air | m3/hr | 0.3 | 0.3 | 0.3 | 0.4 | 0.4 | |

| cooling water | L/min | 50 | 100 | 200 | 300 | 400 | |

| Capacity | production capacity | kg/hr | 50 | 100 | 200 | 300 | 500 |

| Heating temperature | ℃ | 140-190 | |||||

| Heating time | sec | 3~6 | |||||

| Output material’s temperature | ℃ | 30-40 | |||||

| Auxiliary | Control system | ||||||

| Aseptic air supply system | |||||||

| provided by user | Steam | ||||||

| cooling water | |||||||

*1 Size and weight will be different by feed device and collect device. This size is the machine’s size excluding the feed device.

*2 Treatment’s capacity, heating temperature and heating time is different according to different material and physical property.

*3 The control system and aseptic air supply system of different equipment models will be different.

Process Flow of Airflow Instaneously Heating Sterilizer

Cleaning Process of Airflow Instaneously Heating Sterilizer

Airflow Instaneously Heating Sterilizer Videos :

— WHY CHOOSE MINJIE —

A company specialized in research, manufacturing, sales of pharmaceutical, foodstuff, chemical and biotechnology machinery.

- The first factory in China to produce Vacuum Belt Dryer(VBD)

- Developed the first set of Energy-saving Evaporator in China

- 20 years experience in VBD and Evaporator Solution production line

- Rich experience in overseas export and service (over 500 cooperative partners)

- Win large market (over 700 sets Minjie series VBD around the world)

- Supply ability is more than 100 sets VBD per year

- Has a professional technical R&D team,specialized in researching and developing advanced evaporator and drying equipment

- Own many patents and authentication certificates for VBD and Evaporator

- Excellent quality of the products

- GMP standards

- Technical support After-sales Service Provided (Installation instructions, Commissioning, Training)

FAQ

Answer: Minjie engages in research, manufacturing and sales of advanced drying equipment (vacuum belt dryer & thin-layer drying system), low temperature vacuum evaporator and sterilization equipment.

Answer: It is the strength of R&D, the highness of technique, and the standardization of production that synthetically ensures steady quality of Minjie equipment.

Answer: 1 set.

Answer: Consultation, test, technical scheme determination, business negotiation, contract.

Answer: Steam, industrial electricity, water, compressed air.

Answer: CIP cleaning system, automatically and continuously.

Answer: 24-hour service hotline is available. Engineers onsite to guide installation, commissioning and training.

Answer: 1 year after finishing installation and commissioning.