Milk powder, refers to the milk of camel, cattle, goats and other animals as raw materials, through disinfection, degreasing, dehydration, drying and other processes made of powder.

Milk powder drying can be classified according to the different production process and additive materials. It can be divided into blended milk powder drying and ordinary milk powder drying, and skim milk powder can be classified according to the different objects used, including baby milk powder, children milk powder, adult milk powder, milk powder for pregnant women, milk powder for the elderly, and milk powder for pets.

Concentration/Evaporation for camel milk

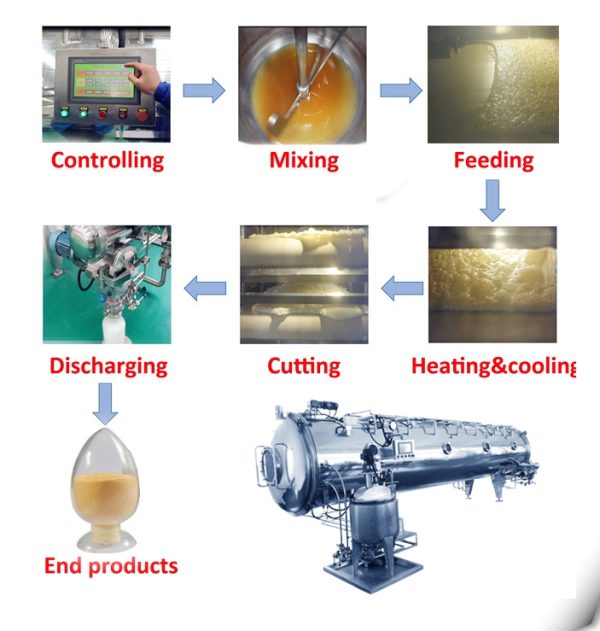

Ultra-low temperature vacuum concentration drying technology is a series of low temperature (20-50℃) state of thin material evaporation, concentration, drying equipment formed by the process collectively. The ultra-low temperature vacuum concentrator adopts the principle of thin film evaporation. Under the vacuum condition, the solvent with low boiling point and light phase component will be evaporated under the low temperature condition, so that the thin material will be concentrated under the low temperature condition, and then the dry material will be obtained through the dryer. Mainly used in pharmaceutical, biological, food and other industries to heat sensitive requirements of the production of products.

Advantages of ultra-low temperature vacuum concentration and drying technology

Compared with traditional spray drying technology, ultra-low temperature vacuum concentration drying technology has significant advantages in terms of nutrient loss, substance Browning, flavor and shape change.

-

Temperature comparison of different processes

Spray drying: 80 ~ 160 °

Low temperature vacuum belt drying: 40~85℃

2. Comparison of heat-sensitive nutrient loss in different processes

Spray drying: 20 ~ 30%(product loss rate /%), 12H/%(Color change rate H/%)

Low temperature vacuum belt drying: 3 ~ 15%(product loss rate /%), 3 ~ 4H%(Color change rate H/%)

-

Comparison of loss of active substances in different processes

Spray drying: 30~50%

Low temperature vacuum belt drying: 3~10%

Different from the traditional drying technology for processing camel milk powder, the temperature control of key processes such as sterilization, concentration and spray drying is higher, and the loss of nutrients is greater, especially the loss of heat-sensitive substances, active substances and other nutrients in camel milk affects the natural quality of camel milk.

The ultra-low temperature vacuum concentration and drying technology introduced by Shanghai MINJIE HI-TECH Company in the specialty dairy industry. Reduced the temperature of milk powder production from standard of 110℃ to less than 40℃, reduced the temperature of the concentration process in the production through vacuum environment, and controls the nutritional loss of the product within 5% through the drying process not higher than 40℃. It maximizes the protection of the original nutritional composition of camel milk, especially the heat-insensitive and active substances, greatly improves the quality of the product and improves the dairy production technology to the world-class level!

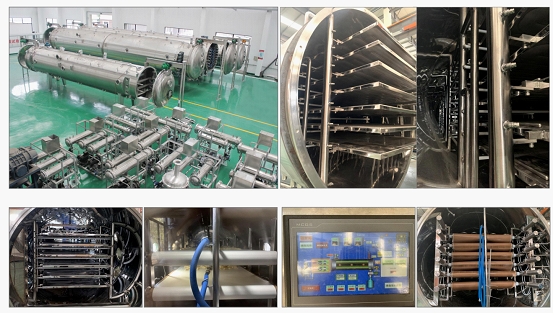

SHANGHAI MINJIE has become a leading manufacturer of Vacuum Belt Dryer & Evaporator since established in 1998.

For any enquiries, please contact: Caroline LI

Email address: globalsales1@shmjjx.com

Mob # /Whatsapp: +86 183-0190-2739