Vacuum low temperature evaporator for botanical extract concentrations are highly recommended all over the world, showing strong growth momentum. Grape seed extract, magnolia officinalis extract, tomato extract, aurantium trifoliate extract, cherry extract, aloe vera extract, ginkgo biloba extract, green coffee bean extract, eucommia ulmoides extract and other plant extracts have been widely used in the production fields of botanical medicine, food additives, functional food, daily chemicals, plant pesticides and veterinary drugs.

Vacuum low temperature evaporator is new concentrating equipment, it realizes low temperature evaporation through high vacuum degree. The top ten concentration are: stevia extract, cranberry extract, eucalyptus oil, capsicum pigment, laurel oil, licorice extract, marigold extract, Chinese fruit extract, milk thistle extract and rutin, From feed to discharge, the whole concentration process is continuous under vacuum state. Vacuum low temperature evaporator conquers many problems met by traditional evaporator, such as, high concentrating temperature, long concentrating time, denaturation of raw material, easy scale formation during concentration, poor fluidity after concentration and no further concentration. Because of the low evaporation temperature in our equipment, active ingredients of the raw material are kept.

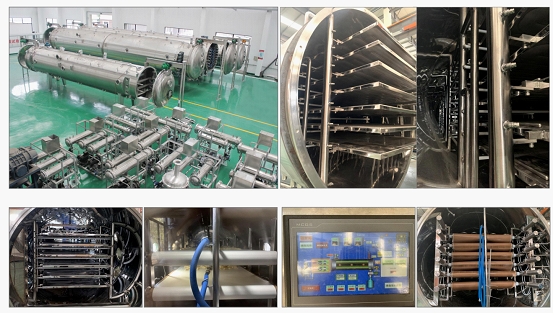

A large amount of ginkgo biloba leaf and green tea extract are adopted by dietary supplement, Vacuum belt dryer is continuous infeed and discharge vacuum drying equipment. Liquid ginkgo biloba leaf and green tea extract are conveyed into dryer body by infeed pump, evenly spread on belts by distribution device. Under high vacuum, the boiling point of the liquid is lowered; water in the liquid material is evaporated. Belts move on the heating plates evenly. Steam, hot water, hot oil can be used as heating media. With the moving of the belts, the product goes through from the beginning evaporating, drying, and cooling to discharging in the end. The temperature decreases through this process, and can be adjusted for different products. Special vacuum crusher is equipped at the discharge end to produce different size end product. The dry powder or granule product can be automatically packed or continue with subsequent process.

Compared with traditional drying method, the main advantages of Vacuum Belt Dryer are as follows:

- Continuous feed-in and discharge in vacuum state

- Complete the drying, crushing, granulating process under vacuum condition

- Automatic, continuous and pipe liningdrying process

- High product quality and ingredient preservation

- Drying temperature adjustable 20℃-150℃

- Parameter set as per different materials

- Continues discharge of dry powder after 30-60 mins.

- Recycling of dry powder can be up to 99%

- Recycling of organic solvent, no discharge, no pollution1/3 operation cost of vacuum ovenand spray dryer

- Suitable for drying of thermal sensitive, high sugar and high viscosity material

- Vacuum crushing technology, avoiding moisture re-absorption, loss and pollution

- No supplementary material, keep the original smell and taste

- Magnificent characteristics of Aroma and instant solubility

- Low labor cost, 2 operators at most

- No pollution of dust and flavor

- PLC automatic control system

- CIP automatic on-line cleaning system

- Meet the requirement of GMP

SHANGHAI MINJIE has become a leading manufacturer of Vacuum Belt Dryer & Evaporator since established in 1998.

For any enquiries, please contact: Caroline LI

Email address: globalsales1@shmjjx.com

Mob # /Whatsapp: +86 183-0190-2739