Vacuum belt dryer is one of the technologies used for manufacturing various vacuum band dried products like malt based products, such as:

Malted Milk Food, Malt Based Food drying, Malt Powder drying,beverage Mix drying and Protein Extracts Gelatin drying. Vacuum Drying is a viable technology that has been used successfully for many years in the food and pharmaceutical industry.

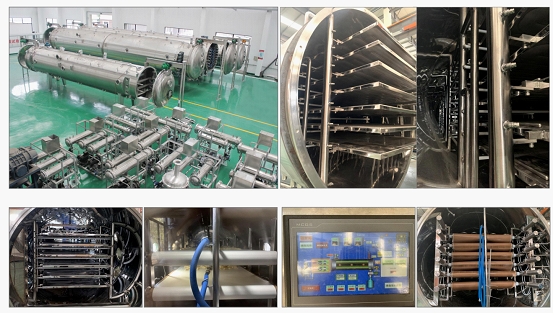

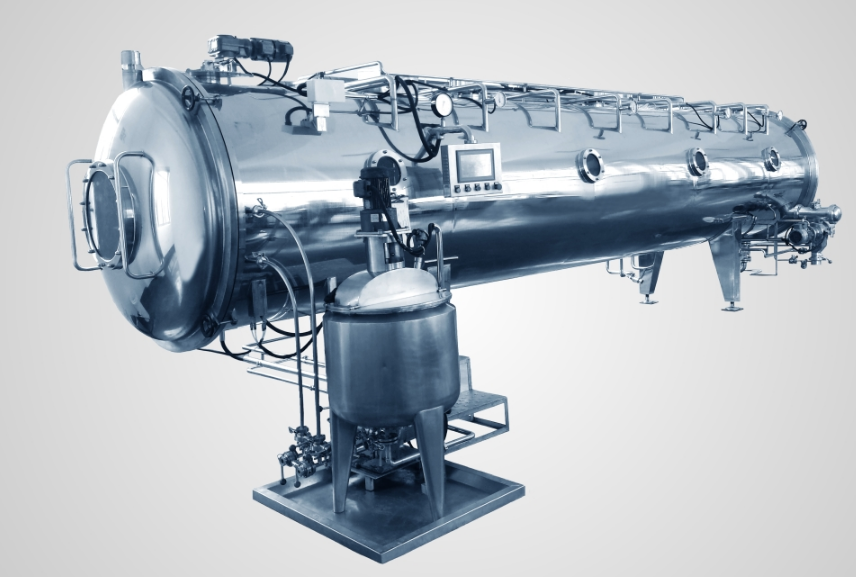

A major advantage to vacuum drying is its energy conservation – less energy is needed for drying, cutting down on the economic and environmental costs associated with drying a product for storage, sale or other purposes. Vacuum drying processes by a belt dryer manufacturer also tend to work faster than other drying methods, cutting down on processing times. Another major advantage of drying materials in vacuum is a less damaging drying process. Some materials can experience problems at high temperatures, such as developing hard, leathery crusts from heat exposure. Low heat under vacuum tends to retain the integrity of the original item without damaging it. For foods and pharmaceuticals, this can be valuable, as other drying processes can degrade quality and make the food less appealing or affect potency of heat-sensitive drug product. Shanghai Minjie Machinery Co., is a leading GMP Vacuum belt drying manufacturer in China.

Vacuum drying is a process in which materials are dried in a reduced pressure environment, which lowers the heat needed for rapid drying.