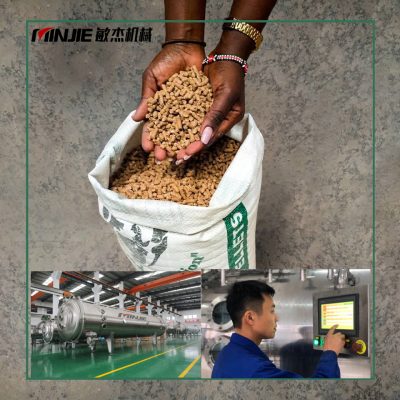

How to dry/dehydrate ecofeed, animal organic feed pellet?

Due to the price hike of imported grains for feed, the production of Ecofeed, feed produced from recycled food waste, has increased in recent years. Food dregs from the food and beverage processing industry and out-of-date food from supermarkets and convenience stores are most often used as raw materials for Ecofeed.

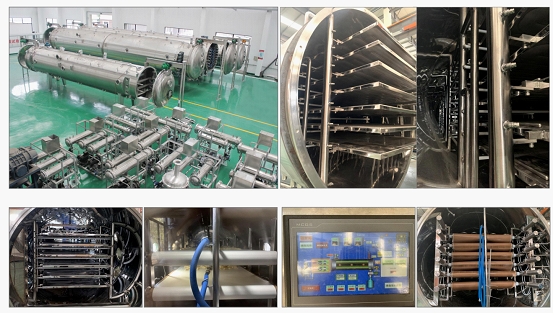

You have ideas to develop your feed additives product. Are you wondering how to dry raw materials with the vacuum belt drying Technology? We are MINJIE, specialist in the vacuum belt dryer production & engineering for the fatty acids! To ensure the stability of product quality, Minjie adopts imported and advanced processing equipment: automatic argon arc machine, automatic laser welder, automatic laser cutter, automatic polisher, CNC machining center and so on.

WE DRY & CRUSH ACCORDING TO YOUR SPECIFICATION

As an animal feed nutritionist and product manager you will have a winning strategy in mind about the best combination of monoglycerides, short and medium chain fatty acids, the drying temperature of vacuum belt dryer is adjustable for different animal feed. It solves the high temperature problem with spray dryer and denaturation problem due to long drying time with traditional drying oven. Colors, solubility, ingredients preservation of the dry product from vacuum belt dryer are incomparable.

we will make the difference by drying your product with most advanced Technology. We strictly check each process of equipment manufacturing, and has gained ISO9001 quality management system’s certification and the EU CE certification, we have quality guarantee to match your specification.

Advantage:

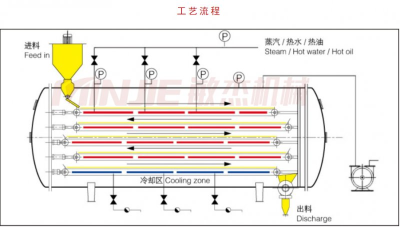

- Bespoke engineered continuous drying solution to fit your requirements

- Continuous and gentle drying preserving maximum colour, flavour and composition, and minimal oxidation

- Individual temperature zones allow for product-specific profiles to be developed suited to each perfectly to each product

- Less energy used than other drying methods

- Viewing windows as standard allow for continuous monitoring, with options for automated monitoring systems available

- Product specific feeding and discharging systems

- Fully PLC automated operation & CIP cleaning system

- GMP standards

Vacuum Belt Dryer Work Flow :

- The first factory in China to manufacture Vacuum Belt Dryer(VBD)

- Developed the first set of Energy-saving Evaporator in China

- 20 years experience in VBD and Evaporator Solution production line

- Rich experience in overseas export and service (over 500 cooperative partners)

- Win large market (over 700 sets Minjie series VBD around the world)

MINJIE VACUUM BELT DRYER &EVAPORATOR

Leading manufacturer and Supplier of Vacuum Belt Dryer& SDR-Evaporator

Contact: +86 18301902739

Whatsapp link: https://wa.me/8618301902739

Email: globalsales1@shmjjx.com