Industrial dryer is the equipment used to perform drying operations, by heating the wet parts of materials to vaporize, in order to obtain the specified moisture content of solid materials, so as to meet the needs of the further processing. According to the different industries, dryers can also be divided into many kinds and have different functions.

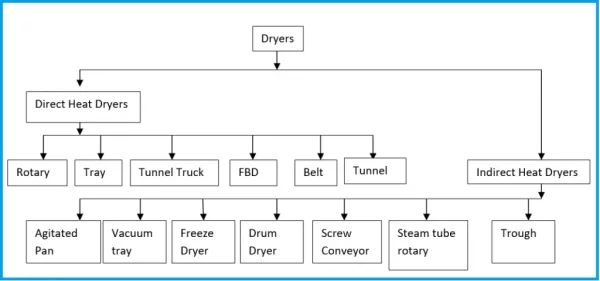

Types of Dryers

Vacuum belt dryer

Vacuum belt dryer is continuous infeed and discharge vacuum drying equipment. Liquid product is conveyed into dryer body by infeed pump, evenly spread on belts by distribution device. Under high vacuum, the boiling point of the liquid is lowered; water in the liquid material is evaporated. Belts move on the heating plates evenly. Steam, hot water, hot oil can be used as heating media. With the moving of the belts, the product goes through from the beginning evaporating, drying, and cooling to discharging in the end. The temperature decreases through this process, and can be adjusted for different products. Special vacuum crusher is equipped at the discharge end to produce different size end product. The dry powder or granule product can be automatically packed or continue with subsequent process.

vacuum drying oven

Operating principle of industrial oven, the operator obtains the internal temperature value of industrial oven through the instrument and temperature sensor, and operates through the control system. It is suitable for small batch intermittent production.

Industrial cabinet oven is a kind of general drying equipment, widely used in the field of industrial production; But not applicable to the strong volatile, flammable and explosive items.

The two disadvantages some customers have been complaining about the cabinet oven are uneven heat distribution and cross contamination.

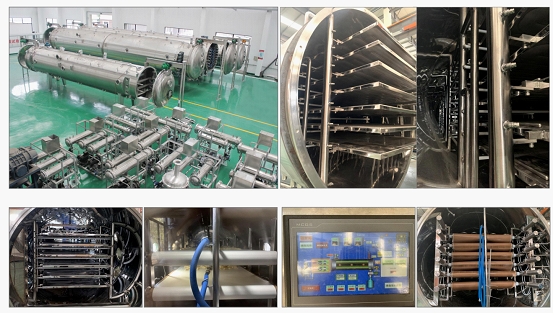

Freeze dryer

Freeze-drying machine is to cool and freeze the material liquid first, then reduce pressure to sublimate the ice and obtain dry materials.

Since the whole process is carried out below freezing point, it is often used for drying heat-sensitive items. Due to the difficulty in heating frozen materials under vacuum and the need for large refrigeration system for condensing and sublimating water vapor under decompression, the drying cost is relatively high. Freeze moisture in highly heat-sensitive materials and keep it below freezing temperature under high vacuum. To sublimate the water and separate it from the material. The material has less active ingredient loss, but the drying rate is low.

Spray dryer

The sprayer is used to disperse the dilute material liquid into fog drops, which settle freely and evaporate rapidly in the thermal stream (air, nitrogen or superheated water vapor), and are finally dried into solid particles separated from the air stream. It also has some disadvantages such as low heat transfer with large equipment; On the other hand, the operation is inflexibility, the heat utilization rate is low and the energy consumption is large.

Rotary dryer

Rotary dryer (also known as drum dryer, rotary dryer, etc.) is a kind of internal heating conduction type drying machinery. In the drying process, the heat from the inner wall of the drum to its outer wall, through the food material attached to the outer wall of the drum to be dried, the water on the material evaporated, is a continuous drying production machinery.

Disadvantages: (1) Large equipment; (2) Installation and disassembly is difficult; (3) Small heat capacity and low thermal efficiency; (4) The material stays in the dryer for a long time, and the difference of the residence time between the material particles is large.

Vacuum belt dryer turn traditional static drying to vacuum dynamic drying, reduce drying time from 10-20 hours to 30-60 minutes. In vacuum belt dryer, the drying temperature is adjustable for different products. It solves the high temperature problem with spray dryer and denaturation problem due to long drying time with traditional drying oven. Colors, solubility, ingredients preservation of the dry product from vacuum belt dryer are incomparable.

SHANGHAI MINJIE has become a leading manufacturer of Vacuum Belt Dryer & Evaporator since established in 1998.

For any enquiries, please contact: Caroline LI

Email address: globalsales1@shmjjx.com

Mob # /Whatsapp: +86 183-0190-2739