Honey is a thick, clear and translucent gelatinous liquid. Among the main components of honey, the water content is below 20%, and the sugars include glucose (24.73%-46.40%), fructose (24.35%-48.16%), sucrose (0-11%) and maltose (0-6%), etc. The total content is 75%-80%, and the ash content is about 0.03%-0.09%. There are also a little of vitamin, amino acid, yeast, pollen grain and waxe, etc. It is a nutrient-rich natural tonic.

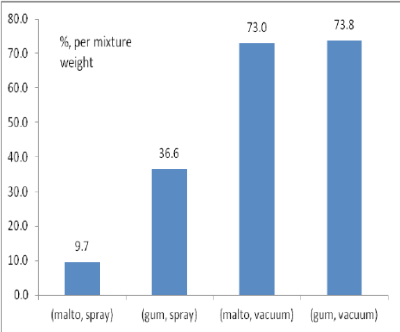

It has been researched and proven by 3 famous scholars from Indonesian Padjadjaran university, that for honey powder produced from vacuum belt dryer and spray dryer, in term of color, aroma, taste and Honey-powder-yield, chemical and physical properties (moisture content, pH, total and reducing sugar content, sugar composition, HMF content, DN), hygroscopic rate and hygroscopicity and hedonic test. The honey powder production by vacuum drying is higher. The addition of Arabic gum increase the higroscopicity of the honey powder compared to the addition of maltodextrin. On the other hand, Arabic gum increases the wetability and dispersing time of the honey powder.

The honey powder production by vacuum drying is higher

An experiment done by MINJIE Lab Center for pure honey drying, there’s no any maltodextrin or Arabic gum added. The test of pure honey drying was quite successful, The quickly moisture absorption of honey powder has been overcome during the special treatment.

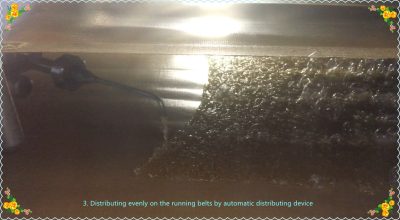

Feed in honey into vacuum belt dryer, distributing evenly on the running belt

Approaching to collection system, crushed to particle size intead of powder

Advantage:

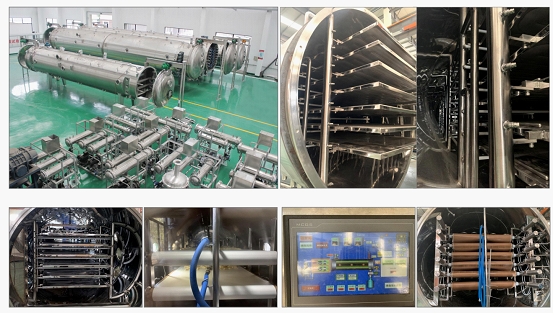

▪ Bespoke engineered continuous drying solution to fit your requirements

▪ Continuous and gentle drying preserving maximum colour, flavour and composition, and minimal oxidation

▪ Individual temperature zones allow for product-specific profiles to be developed suited to each perfectly to each product

▪ Less energy used than other drying methods

▪ Viewing windows as standard allow for continuous monitoring, with options for automated monitoring systems available

▪ Product specific feeding and discharging systems

▪ Fully PLC automated operation & CIP cleaning system

▪ GMP standards

SHANGHAI MINJIE has become a leading manufacturer of Vacuum Belt Dryer & Evaporator since established in 1998.

For any enquiries, please contact: Caroline LI

Email address: globalsales1@shmjjx.com

Mob # /Whatsapp: +86 183-0190-2739