Health food powders are used in everyday life in many ways and offer technological solutions to the problem of food production. The main purpose of drying food is to lower their moisture content to a particular level that will exclude the growth of microorganisms.

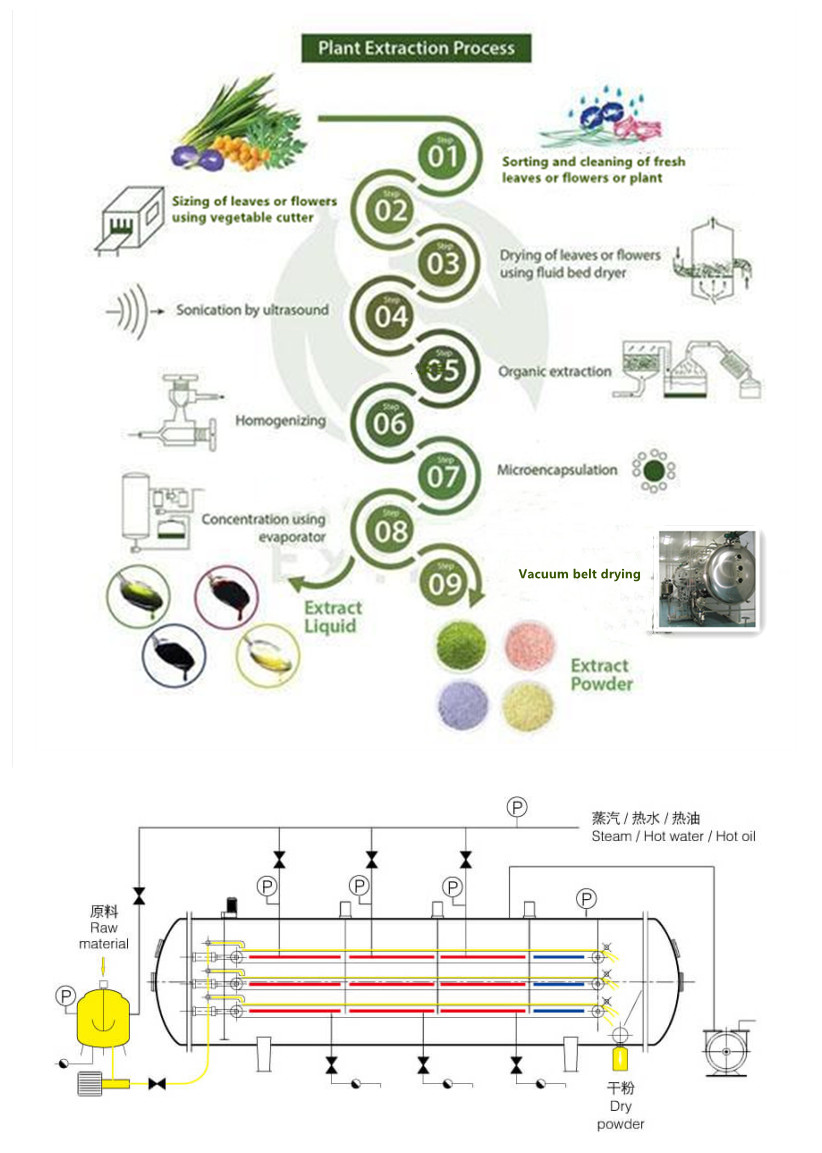

Normally the plant extraction process will go with below steps, with the last step of drying process, the final powder product will be produced.

- Sorting and cleaning of fresh leaves or flowers or plant

- Sizing of leaves or flowers using vegetable cutter

- Drying of leaves or flowers using fluid bed dryer

- sonication by ultrasound

- Organic extraction

- Homogenizing

- Microencapsulation

- Concentration using evaporator

- Vacuum belt drying

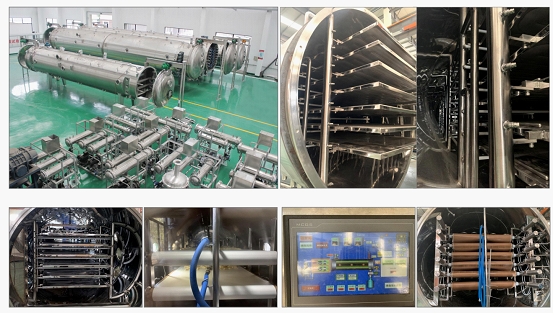

Comparing with the traditional drying method, there’re chief advantages listed as below:

- Continuous feed-in and discharge under vacuum state

- Pipelined, continuous and automated drying process

- Dry, Comminute and Granulate under vacuum state

- No denaturation for thermosensitive materials

- Suitable for the liquid and paste with high viscosity

- 1/3 running cost of vacuum oven or spray dryer,1/6 of freezing dryer

- Labor saving, 1 or 2 operators on site

- Adjustable temperature 30-150℃

- Continuous discharge of dry powder after 30-60 minutes, 99% yield

- CIP system, GMP standards

Contact Minjie: Caroline Li WhatsApp/Mob#: +86-18301902739 Skype:miamiaha Email Add: globalsales1@shmjjx.com