In the recent years, low temperature pesticides liquid drying equipment have gained interest as a promising alternative to conventional dehydration dryer machine especially for Emamectin benzoate (EB), which is a semi-synthetic derivative of abamectin of the avermectin family of 16-membered macrocylic lactones. The current commercial formulations of EB are sensitive to the light and temperature. Therefore, it is an urgent need to use low temperature vacuum belt dryer that could solve drying process technical issues including easy agglomeration or thermoplastic, thermal sensitivity, easy oxidation/explosion, strong stimulation, high toxicity, and for material needing solvent recycling.

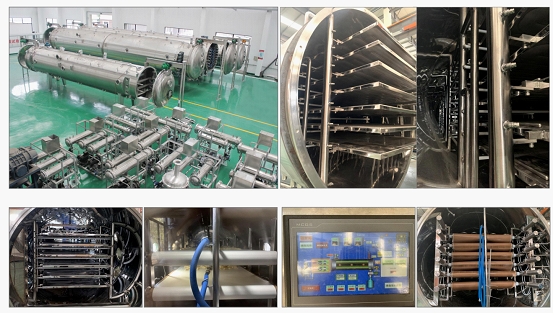

low temperature vacuum belt dryer

Emamectin benzoate drying experiment

–video taken from Minjie laboratory, the largest vacuum belt dryer manufacturer in China

The Emamectin benzoate (EB) gel was dried by using MJY5-2 low temperature vacuum belt dryer under vacuum for about 40 minutes to obtain powder. It solves the high temperature problem with spray dryer and denaturation problem due to long drying time with traditional drying oven/cabinet. Colors, solubility, ingredients preservation of the dry product from vacuum belt dryer are incomparable.

Compared with traditional drying method, the main advantages of Vacuum Belt Dryer are as follows:

- Continuous feed-in and discharge in vacuum state

- Complete the drying, crushing, granulating process under vacuum condition

- Automatic, continuous and pipe liningdrying process

- High product quality and ingredient preservation

- Drying temperature adjustable 20℃-150℃

- Parameter set as per different materials

- Continues discharge of dry powder after 30-60 mins.

- Recycling of dry powder can be up to 99%

- Recycling of organic solvent, no discharge, no pollution

- 1/3 operation cost of vacuum ovenand spray dryer

- Suitable for drying of thermal sensitive, high sugar and high viscosity material

- Vacuum crushing technology, avoiding moisture re-absorption

- No supplementary material, keep the original smell and taste

- Magnificent characteristics of Aroma and instant solubility

- Low labor cost, 2 operators at most

- No pollution of dust and flavor

- PLC automatic control system

- CIP automatic on-line cleaning system

- Meet the requirement of GMP

SHANGHAI MINJIE has become a leading manufacturer of Evaporator &Vacuum Belt Dryer since established in 1998.

For any enquiries, please contact: Caroline LI

Email address: globalsales1@shmjjx.com

Mob # /Whatsapp: +86 183-0190-2739