In the production of Ovaltine, the drying process is quite important. Malted with milk and eggs, after seasoning with cocoa, the mixture will go through vacuum drying technology to get the final drinking beverage. It is a super popular instant chocolate malt cereal drink. In addition to Ovaltine, Milo, Cola Cao, Hollick, Lecofu also produce malt based drink, through mixing, emulsification, sterilization, degassing concentration, vacuum drying, crushing and packaging.

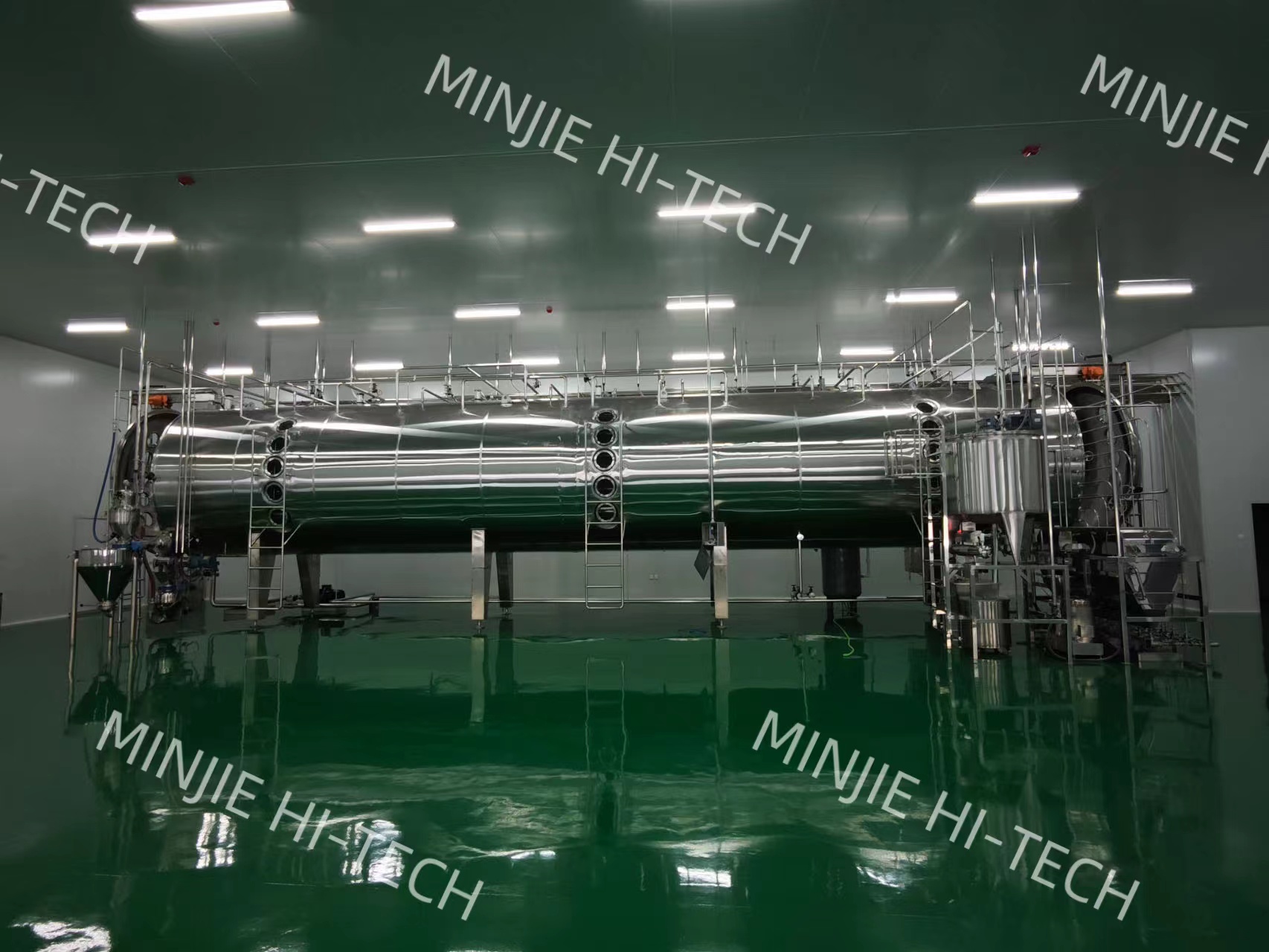

Vacuum belt dryer is continuous infeed and discharge vacuum drying equipment. Liquid product is conveyed into dryer body by infeed pump, evenly spread on belts by distribution device. Under high vacuum, the boiling point of the liquid is lowered; water in the liquid material is evaporated. Belts move on the heating plates evenly. Steam, hot water, hot oil can be used as heating media. With the moving of the belts, the product goes through from the beginning evaporating, drying, and cooling to discharging in the end. The temperature decreases through this process, and can be adjusted for different products. Special vacuum crusher is equipped at the discharge end to produce different size end product. The dry powder or granule product can be automatically packed or continue with subsequent process.

Contact Person: Caroline Li WhatsApp/Mob#: +86-18301902739 Skype:miamiaha Email Add: globalsales1@shmjjx.com