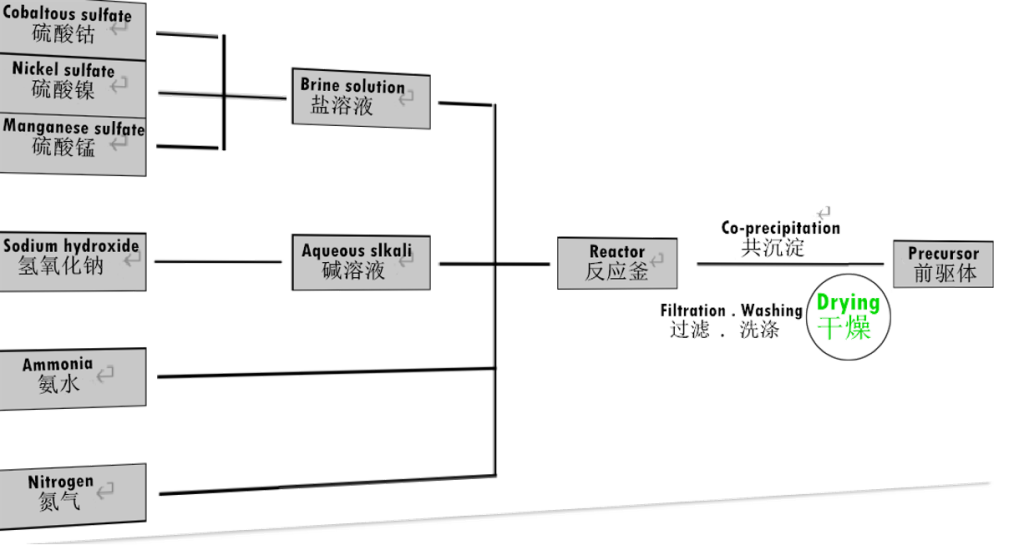

The PH value of the synthesized ternary precursor slurry is about 11, which belongs to alkaline slurry. The main alkaline substances are NaOH and ammonia.

Filtering and Washing Equipment

Filtration and washing equipment is to achieve solid-liquid separation of the precursor slurry obtained by the reaction, and then wash the obtained precursor cake with washing liquid to remove the sulfate, chlorine, sodium ions etc which remain in the cake.

Filtration and washing equipment mainly include filter press, centrifuge, microporous filter, filtration and washing “two-in-one” equipment.

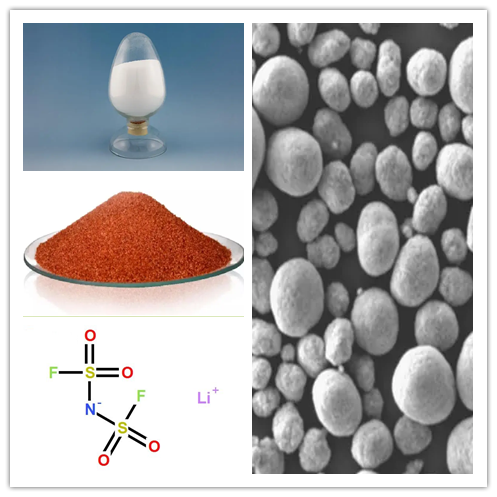

Drying Process

The precursor of ternary material is a low-priced compound of variable metal, which will be oxidized in the air, and the higher the drying temperature, the more serious the oxidation degree. The drying temperature of precursor cake in the air should be less than 150℃. When the temperature reaches 400℃, the precursor will be oxidized to trivalent oxide.

Drying Equipment

The selection of ternary material precursor dryer needs to consider at least the following points:

The moisture content requirements of the product;

The moisture content of filter cake and whether the water content of filter cake is uniform;

Dryer’s production capacity, material feed mode;

Dryer and ternary material precursor contact part of the material need to be alkali resistant, and can not be brought into metal impurities or other impurities;

The drying temperature that needs to be achieved.

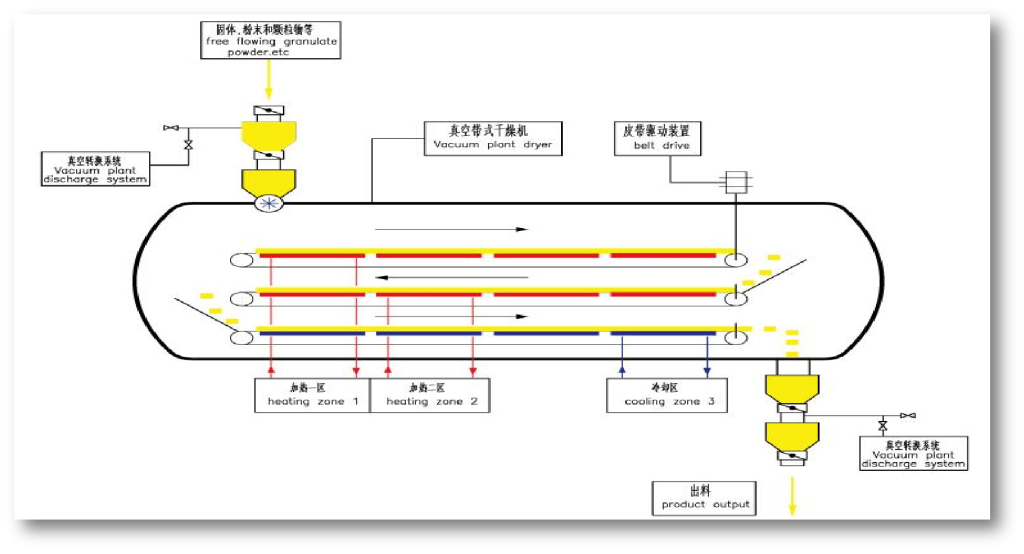

The precursors of ternary materials can be dried by hot air circulation oven, rotary dryer, disk dryer, rake dryer, microwave dryer, etc. But the vacuum low-temperature belt dryer can avoid metal pollution with efficient drying time.

Low-Temperature Vacuum Belt Dryer Features:

- Effective control of magnetic foreign bodies and metal impurities in terminal products

- During the whole drying process, the material is in a relatively static state to preserve the crystal shape of the product to the greatest extent

- Continuous drying, gradient heat transfer, all on-line parameters controllable

- The drying time is short (60-150min) at the temperature allowed by the product (40-250℃)

- Clean, pollution-free production conditions and online recovery of organic solvents (continuous drying, closed system, effective in-place cleaning)

- Drying under vacuum environment, reducing the entry of carbon dioxide, ensuring the product quality

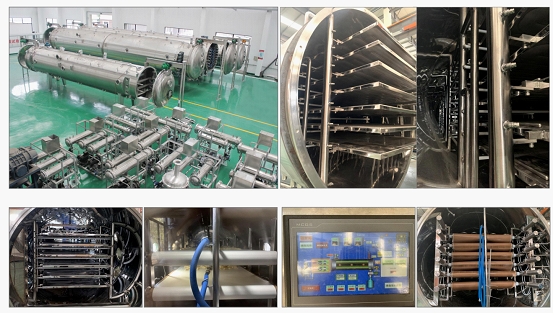

MINJIE VACUUM BELT DRYER &EVAPORATOR

Leading manufacturer and Supplier of Vacuum Belt Dryer& SDR-Evaporator

Contact: +86 18301902739

Whatsapp link: https://wa.me/8618301902739

Email: globalsales1@shmjjx.com