With the rise of the national new energy industry, more and more new energy and new materials companies are looking for more advanced process equipment to solve the drying problem of new energy materials such as lithium hydroxide and lithium fluoride. Vacuum low-temperature solids The emergence of continuous vacuum belt dryers will completely solve the problems of poor material stability, easy agglomeration, uneven moisture content, and color discoloration caused by traditional double-cone dryers, vacuum rake dryers and other drying methods that directly affect product quality.

Recently, more than a dozen companies in the lithium battery industry have contacted our company, eagerly hoping to solve the drying problem in the process, for example: lithium carbonate products:

Client: A company in Jiangsu

Material: Lithium carbonate, raw material for lithium battery

Equipment: Vacuum low temperature continuous dryer for particles

Lithium carbonate, an inorganic compound with the chemical formula Li2CO3, is a colorless monoclinic crystal or white powder. The melting point is 723°C (1.013*10^5Pa). Soluble in dilute acid. Slightly soluble in water, the solubility in cold water is greater than that in hot water. Insoluble in alcohol and acetone. It can be used to make ceramics, medicines, catalysts, etc. Commonly used raw materials for lithium-ion batteries.

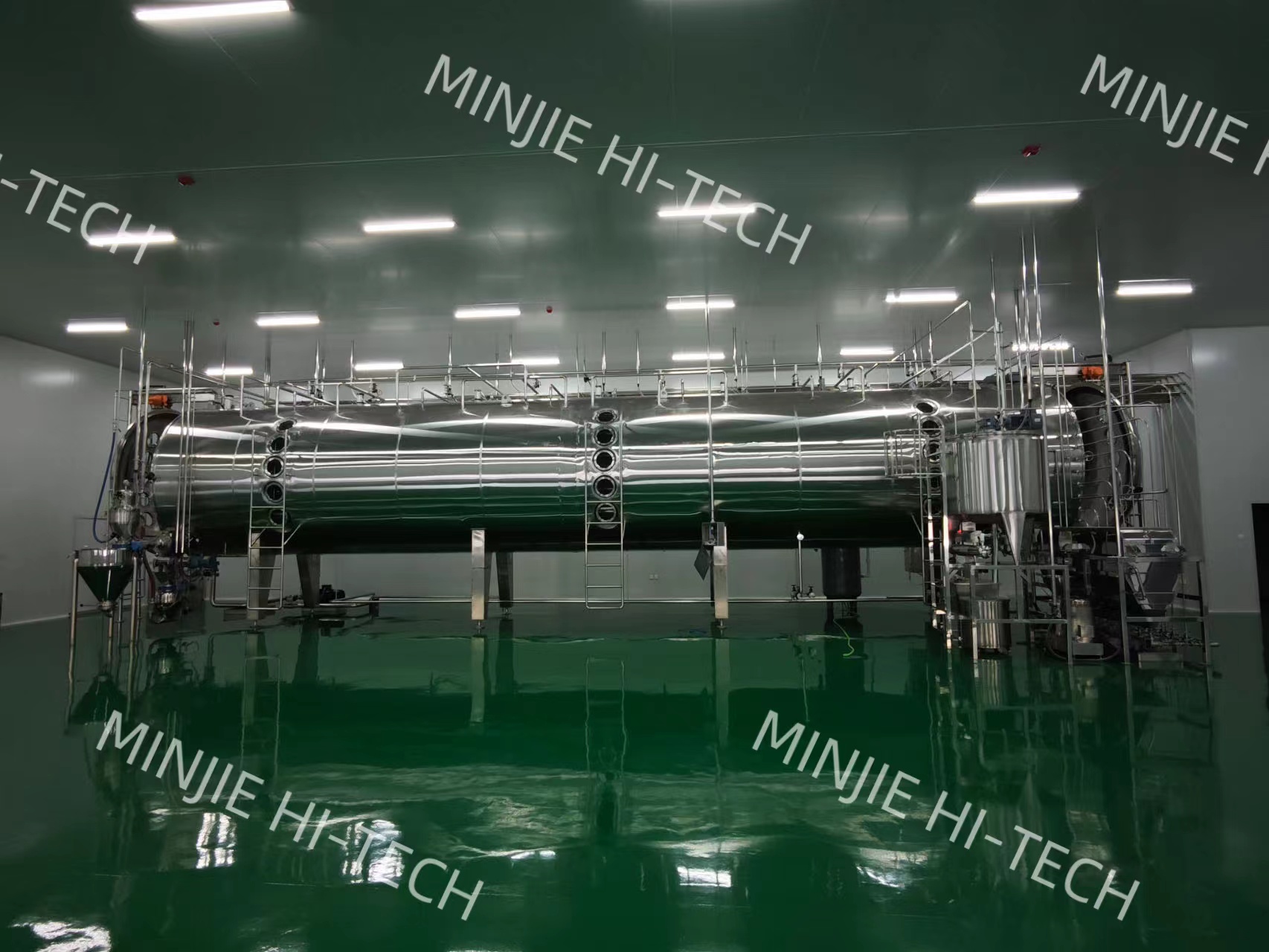

The material used in this test is lithium carbonate used as a raw material for lithium electronic pools. The equipment used for the test is Shanghai Minjie’s vacuum low-temperature solid continuous dryer equipment. The test material lithium carbonate solvent is water, and a reasonably designed continuous feeding device and distributor are used. Distribute the lithium carbonate, the raw material of the lithium battery that the customer needs to dry, evenly on the conveyor belt, control the temperature at 50-60 degrees, and realize continuous feeding in a vacuum state. The material is continuously discharged through the processes of evaporation, drying, and cooling. Due to the full vacuum, dust flying is avoided, product yield is increased, and pollution problems are solved.

The raw material lithium carbonate dried by a vacuum low-temperature solid continuous dryer has reached the customer’s requirements in terms of dry humidity and dry temperature, and has been unanimously recognized by customers!

- Realize continuous feeding and continuous discharging under vacuum conditions

- Realize the automation, continuity, and pipelineization of the drying process

- The drying process temperature is adjustable at 20-150℃

- The operating cost is one-third of the traditional drying process

- Product yield reaches more than 99%

- Drying time 20-80 minutes adjustable

- Greatly reduce labor costs

- Adopt PLC automatic control system

- Reduced the links of product pollution caused by complex drying process

- Realize the solvent recovery requirements in the product drying process

- Online automatic cleaning, in line with GMP requirements

- Scope of application: Chinese medicine, western medicine, food, chemical and other enterprises

- Various solids, crystals, granules, powders, pastes, pills, fruits and other raw materials

- Easily oxidized, explosive, strong irritant, highly toxic materials

- Products that need to recycle various solvents

Shanghai Minjie Pharmaceutical Machinery Co., Ltd. was established in 1998 and is a high-tech enterprise integrating R&D, manufacturing and sales. It mainly produces various special low-temperature drying and high-efficiency concentration equipment for pharmaceutical, food, biological, chemical, health care and other industries. Since the company was founded, it has received extensive support from all walks of life. With the joint efforts of all employees, the company has achieved rapid development. Received the attention and affirmation of domestic and foreign customers, advanced design concepts and superb manufacturing technology have created the continuous development and growth of Minjie in the high-tech field. We will continue to pursue, make unremitting efforts, use innovation, create high Precise first-class products report to users and serve the society.