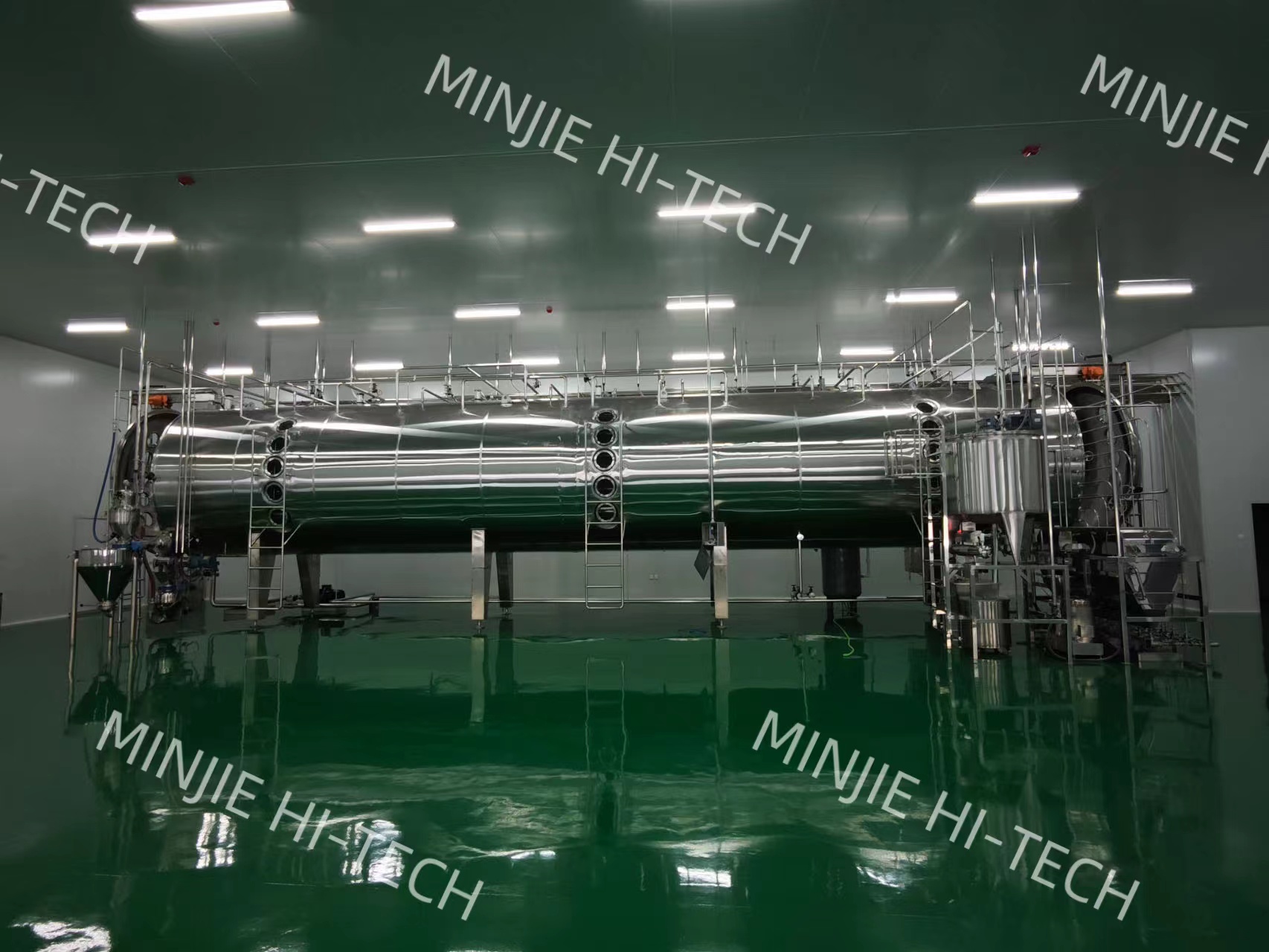

For honey, which is relatively viscous and has a high sugar content, there will be a certain degree of difficulty in the drying process. Many equipment on the market cannot do it. However, the honey drying and drying equipment produced by Shanghai Minjie Machinery Co., Ltd. It can dry honey well. Shanghai Minjie Pharmaceutical Machinery Co., Ltd. provides a free test base, you can bring materials for free test!

The principle of honey drying equipment:

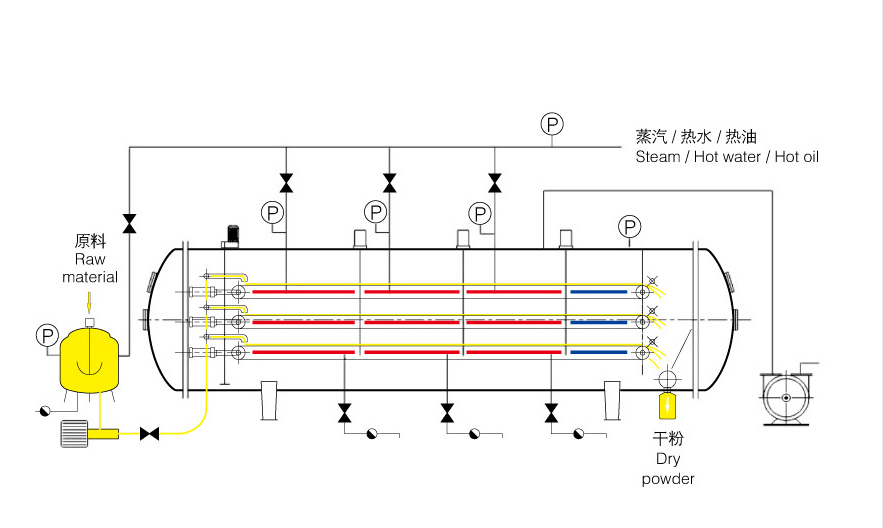

The vacuum cryogenic liquid continuous dryer is a vacuum drying equipment with continuous feeding and continuous discharging. The liquid raw materials are transported to the dryer through the feed pump, and are evenly distributed on the conveyor belt through the distributor. The high vacuum reduces the material The boiling point temperature, the moisture of the liquid raw material is directly sublimated into gas. The conveyor belt runs at a uniform speed on the heating plate. The heat source in the heating plate can be steam, hot water or electric heating. Through the operation of the conveyor belt, the evaporation and drying from the front end to the cooling at the back end The temperature range for discharging is from high to low, which can be adjusted according to the characteristics of the material. The discharge end is equipped with a specific vacuum pulverizing device to reach the finished product of different particle sizes. The dried powder can be automatically packed or subsequent processes.

The birth of the vacuum cryogenic liquid continuous dryer transforms the traditional static drying into vacuum dynamic drying. The product is dried from the traditional 10-20 hours to 30-60 minutes to produce the product, achieving different drying temperatures according to different materials. The goal is to solve the problem of high spray drying temperature and easy denaturation of traditional oven for long time. The color, solubility, and physical properties of the dried product are unmatched by other equipment.

Process flow of honey drying equipment:

Technical parameters of honey drying equipment:

| Model | Diameter | Length | Height | Heating area | Heating temperature | Moisture content of feeding material | Moisture content of dried product | Heating | Water Evaporation | Dryer body power |

| mm | mm | mm | ㎡ | ℃ | % | % | kg/h | kw | ||

| MJY30-4 | 1700 | 9800 | 2700 | 30 | 30-150 Adjutable | 20-80 with liquidity | 0.2-5 Adjustable |

Steam or Hot water or Hot oil | 15-25 | 10 |

| MJY60-6 | 2200 | 10800 | 3650 | 60 | 45-55 | 14 | ||||

| MJY80-6 | 2200 | 13500 | 3650 | 80 | 60-75 | 14.5 | ||||

| MJY100-6 | 2200 | 16100 | 3650 | 100 | 80-90 | 15.5 | ||||

| MJY120-7 | 2200 | 16100 | 3650 | 120 | 100-110 | 16.5 | ||||

| MJY160-8 | 2800 | 17300 | 4100 | 160 | 120-140 | 18.5 | ||||

| MJY200-10 | 2800 | 17300 | 4150 | 200 | 160-180 | 25.5 |

Consignment of VBD

https://air.alibaba.com/apps/alimsc/private-marketing/feeds-detail.html?wh_weex=true&contentId=289800038509