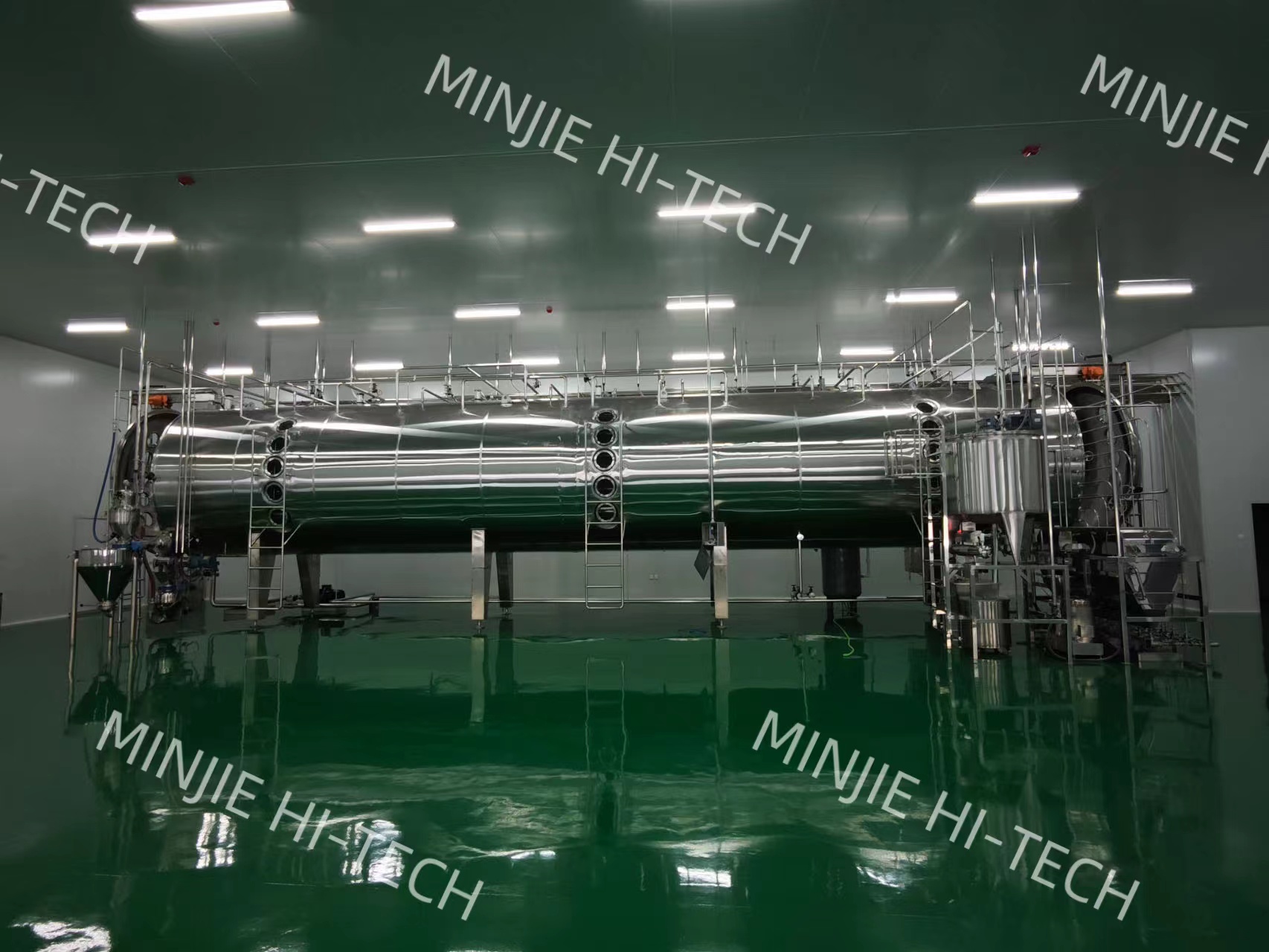

With more than 20 years of technology accumulation, Minjie, as a manufacturer of low-temperature drying equipment of fermentation broth vacuum dryers, has continuously visited customers, collected the problems encountered by customers in the drying process, and carried out the advantages and disadvantages of conventional spray drying and freeze drying. After repeated comparisons, a completely new concept vacuum belt low-temperature drying equipment was finally developed. Once used, the equipment has been well received by customers, serving Nestlé, AB Food (British United Food Group), Indonesia PT.MAYORA, Ukraine TB Fruit, China Resources Sanjiu Group, Hongri Pharmaceutical, Sunflower Pharmaceutical, Shanghai Pharmaceutical Group, German Doehler Group and other well-known enterprises in various industries at home and abroad.

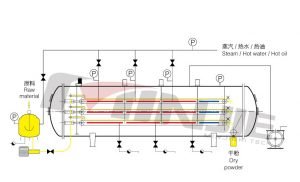

The fermentation broth vacuum dryer produced by Shanghai Minjie Pharmaceutical Machinery Co., Ltd. is a vacuum drying device with continuous feeding and discharging. The liquid raw material is transported to the dryer through the feed pump and is evenly distributed through the distributor. The material is distributed on the conveyor belt through high vacuum to reduce the boiling point temperature of the material. The moisture of the liquid raw material is directly sublimated into gas. The conveyor belt runs at a uniform speed on the heating plate. The heat source in the heating plate can be steam, hot water or electric heating. Operation, from evaporation and drying at the front end to cooling and discharging at the back end, the temperature range is from high to low, which can be adjusted according to the characteristics of the material. The discharge end is equipped with a specific vacuum crushing device to reach the finished product of different particle sizes, and the dried powder Materials can be automatically packed or follow-up processes.

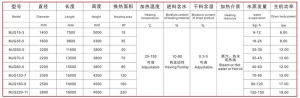

Technical parameters of low temperature drying equipment for fermentation broth vacuum dryer:

Fermentation liquid vacuum dryer low temperature drying equipment is suitable for drying more than 200 kinds of food, chemicals, medicines, etc.

Various vegetable soups, yeast extract: carrots, beets, celery, onions, garlic, tomatoes, condiments, beef bones, pork bones, chicken essence, instant soup mixtures, yeast, rhubarb, various proteins (amino acids), etc.;

Juice (fruit) concentrate-non-alcoholic beverages, pastries: beverages, pastries, ice cream, cakes, yogurt, etc., fruit juice powder (apple, pear, apricot, orange, grape, lemon, papaya, mango, etc.) , Black rice fruit, pectin, etc.

Chemical products: synthetic lysine (L lysine), anti-biomass, powder natural paint

Products containing cocoa and sugar: milk powder, coffee, high-calorie fruits, saccharin, sweeteners, chocolate (cocoa)

Enzymes, vitamins, beer brewing aggregates, intermediate products: amylase, intermediate products of vitamin roots, intermediate products of natural vitamin roots, natural vitamin mixtures, brewer’s yeast, malt extract (maltose, wort), Hop essence

Medicinal plant essences: Chinese medicine essence, aloe vera, tonic agents containing various vitamins, horse chestnut fruit