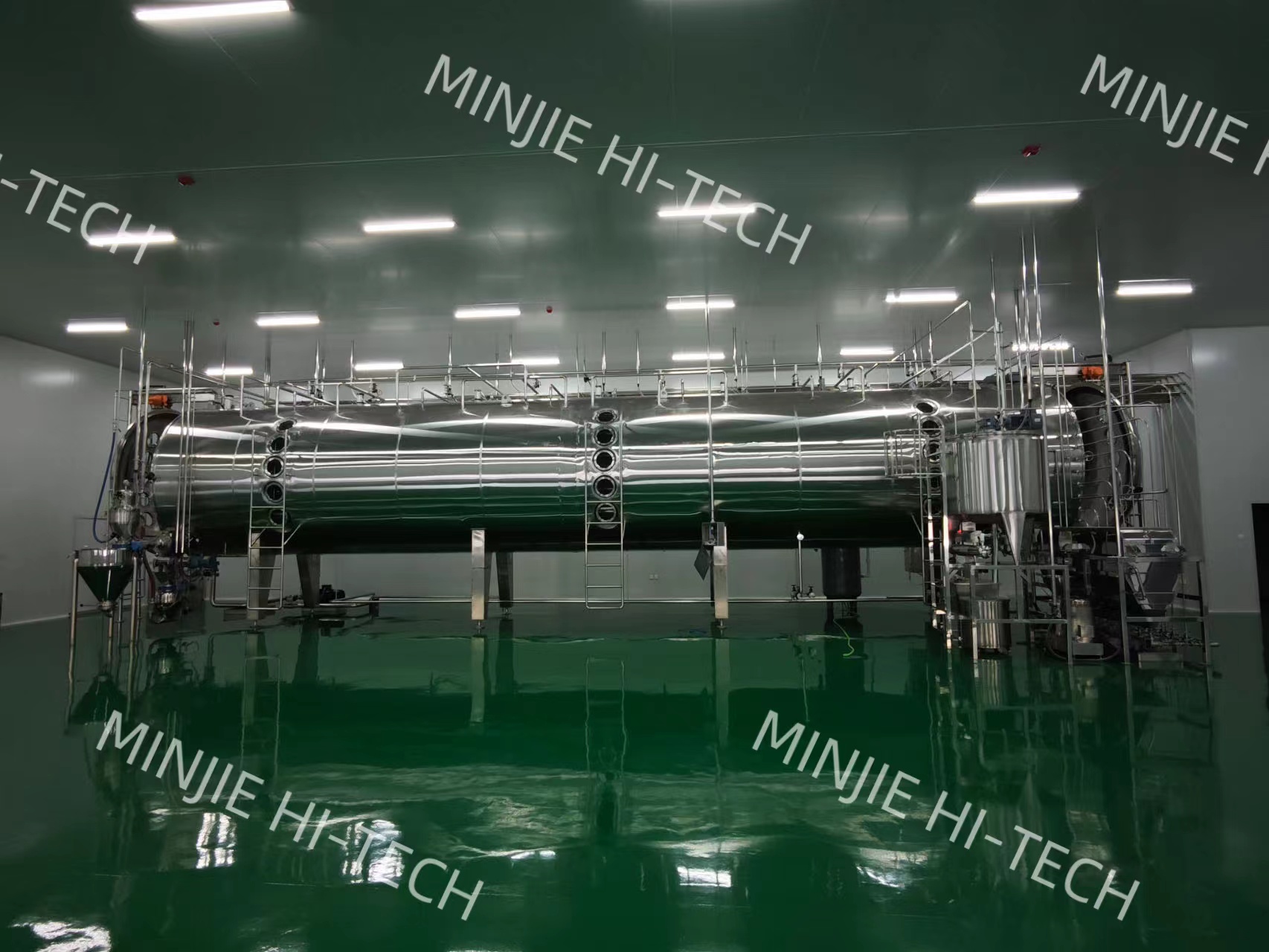

While the peers were still complacent in the traditional drying and concentration process, Minjie resolutely combined traditional technology with modern technology through continuous innovation, and produced a high-efficiency, energy-saving, environmentally friendly and safe product. Such as API vacuum drying equipment | API belt dryer, these products can not only replace traditional drying and concentration equipment, but also can process some materials that cannot be solved by traditional technology. At the same time, it also saves a lot of costs for users. Automatic operation, automatic cleaning, the process only needs 1-2 people, which saves a lot of labor costs for the company. Environmental protection is a big issue and an important issue that runs through the development of our global enterprises. Due to the vacuum state, our equipment avoids dust pollution and realizes the recovery of solvents at the same time. Therefore, it is currently the most advanced drying equipment at home and abroad.

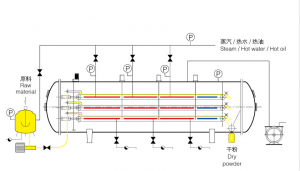

API vacuum drying equipment | Working principle of API belt dryer:

Vacuum belt dryer is a continuous infeed and discharge vacuum drying equipment. Liquid product is conveyed into dryer body by infeed pump, evenly spread on belts by distribution device. Under high vacuum, the boiling point of the liquid is lowered; water in the liquid material is evaporated. Belts move on the heating plates evenly. Steam, hot water, hot oil can be used as heating media. With the moving of the belts, the product goes through from the beginning evaporating, drying, cooling to discharging in the end. The temperature decreases through this process, and can be adjusted for different products. Special vacuum crusher is equipped at the discharge end to produce different size end product. The dry powder or granule product can be automatically packed or continue with subsequent process.

API vacuum drying equipment | API belt dryer compared with traditional technology

|

Minjie Vacuum Low Temperature Continuous Dryer: 1. Solve the drying of difficult raw materials 2. Pipeline, continuity, and automation 3. Realize the integration of drying, crushing and granulating 4. Ultra-low temperature can better preserve product quality 5. Low energy consumption, safe and environmentally friendly 6. Online automatic cleaning, in line with pharmaceutical GMP |

Traditional drying process 1. Intermittent production and complex process links 2. High temperature, long time, product variability 3. Manual feeding and discharging, labor-intensive 4. High operating energy consumption and potential safety hazards 5. Large dust on site and low recovery rate |

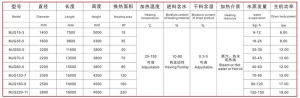

API vacuum drying equipment|Technical parameters of API belt dryer:

Customers are welcome to bring materials to our factory for testing. We, Shanghai Minjie Pharmaceutical Machinery Co., Ltd., have a test base that can do tests for you for free, and at the same time, we can customize drying equipment according to your needs. We welcome your arrival!