In industries handling slurry materials (e.g., pharmaceuticals, food extracts, ceramics), traditional drying methods like spray drying often fail due to clogging, thermal degradation, or poor solubility. Shanghai Minjie’s vacuum belt dryer (VBD) offers a breakthrough, preserving product quality while achieving uniform moisture removal.

[Key Advantages of Vacuum Belt Drying for Slurries]

-

Non-Clogging Processing

Unlike spray drying machines, which struggle with high-viscosity slurries, our vacuum belt drying system transports materials continuously on a heated belt under low-pressure conditions, preventing nozzle blockages and uneven particle formation. -

Low-Temperature Drying

Operates at 40–80°C (vs. 150–200°C in spray dryers), ideal for heat-sensitive compounds like plant extracts, probiotics, or polymer gels. -

High Retention of Active Ingredients

Vacuum environment minimizes oxidation, preserving bioactive compounds, flavors, and colors—critical for nutraceutical drying and specialty chemicals.

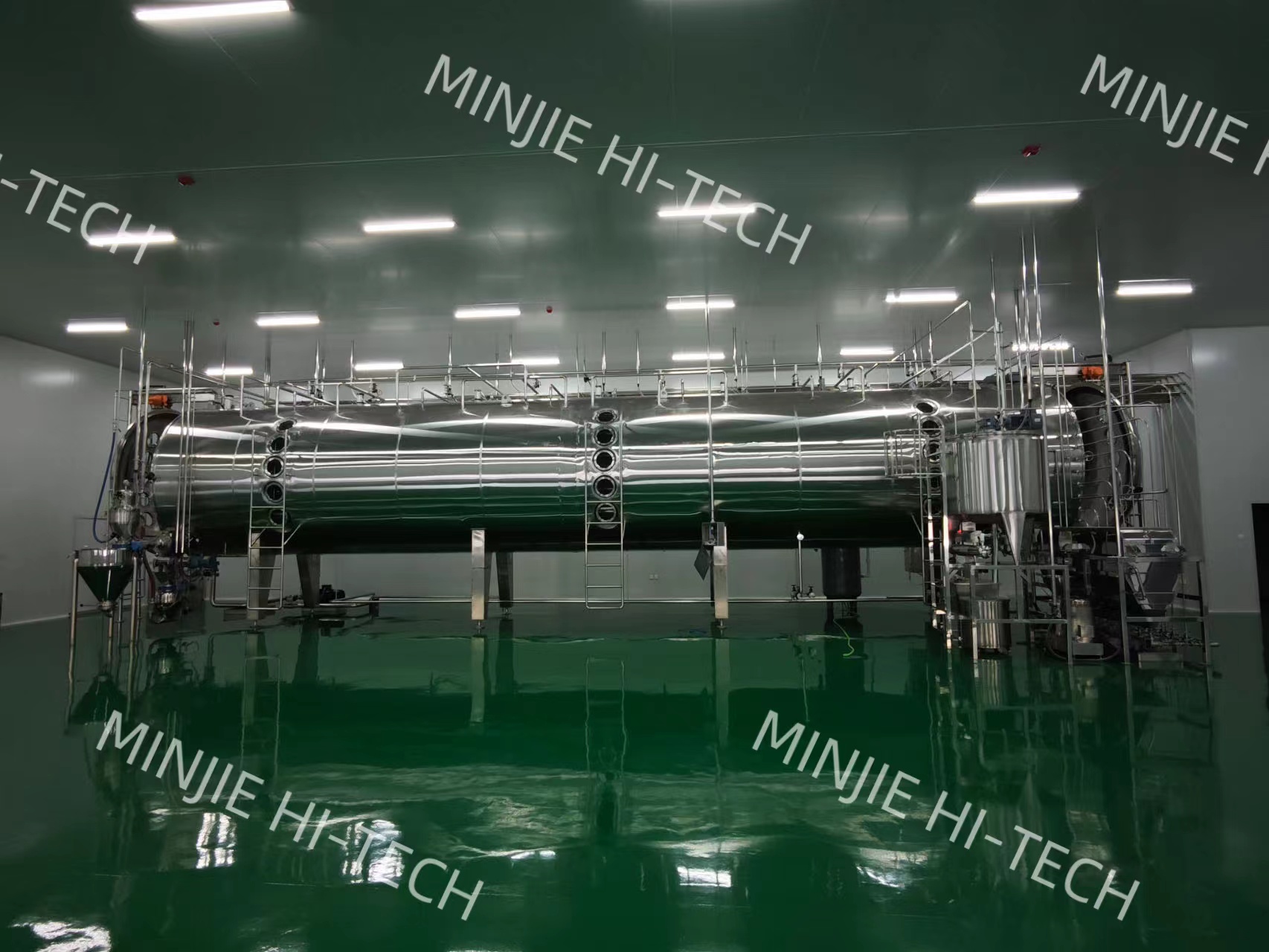

[Visual Case Study: Drying Process]

(Caption for your image)

Image Title: “Step-by-Step Slurry Drying with Minjie VBD Technology”

-

Step 1: Pumping slurry onto the temperature-controlled belt.

-

Step 2: Gradual evaporation under vacuum, forming a porous dried layer.

-

Step 3: Crumbling & collecting the final product with >99% solubility.

[Technical Comparison]

| Parameter | Vacuum Belt Dryer | Spray Dryer |

|---|---|---|

| Max Viscosity | 50,000 cP | <500 cP |

| Energy Efficiency | 30% higher | Lower |

| Output Form | Flakes/Powder | Fine powder |

[Call to Action]

Upgrade your drying process with Minjie’s customized vacuum belt drying solutions

—contact our engineers at [email:tmj@shmjjx.com]

-whatsapp:86-13917588675

-visit [website:https://www.mjdryer.com/product/vacuum-belt-dryer-for-liquid-paste/ ]

welcome to contact us for a free material test.

-

Primary: vacuum belt dryer for slurries, spray drying alternative, slurry drying machine, low temperture vacuum dryer, industrial dehydration equipment, sticky material dryer