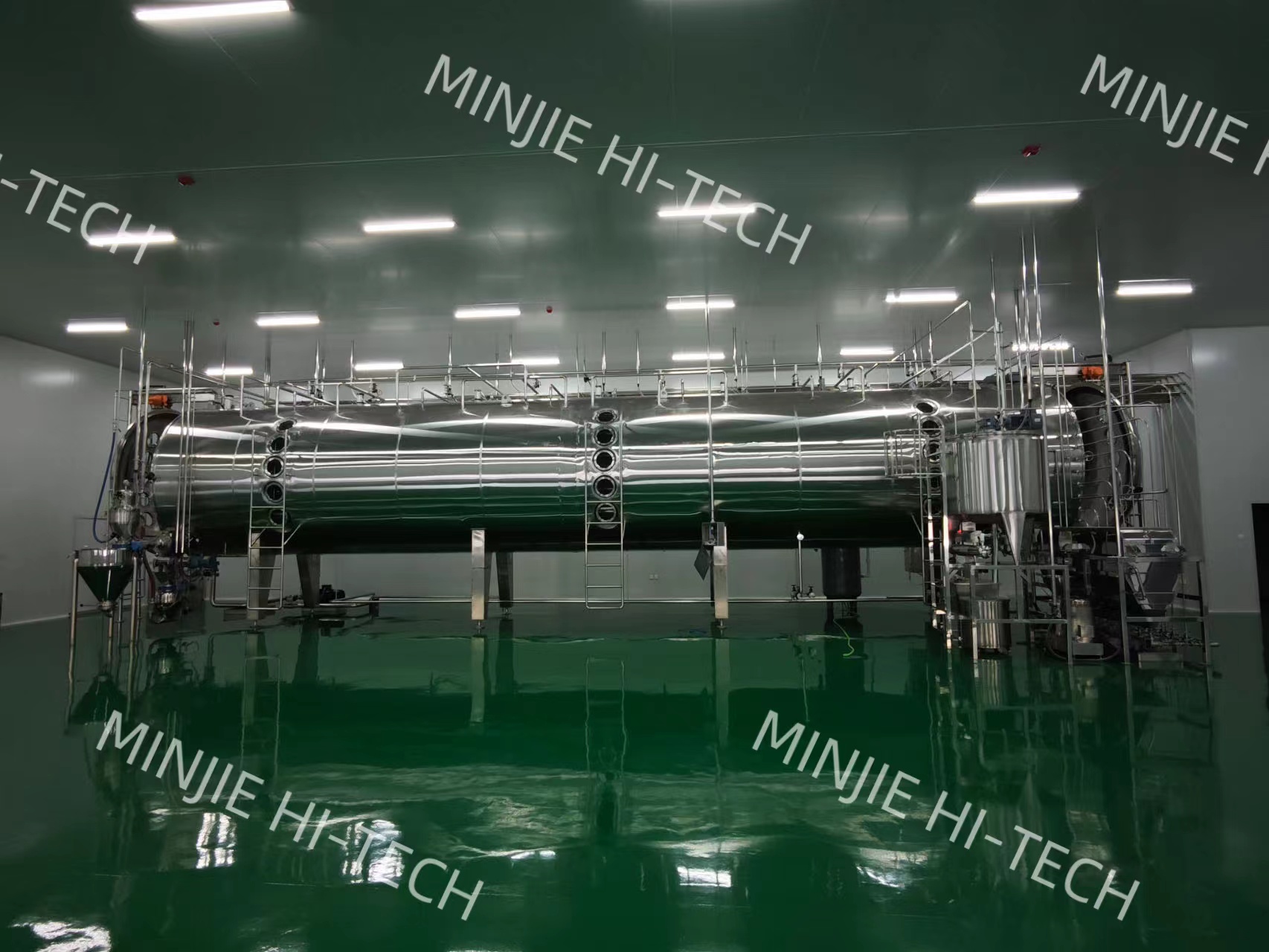

The MJ series fully automatic vacuum belt dryer is a brand new concept which can realize energy saving and low temperature drying, it is developed from deep research and analysis of the advantages and disadvantages of conventional spray dryer and freeze dryer.

During drying traditional Chinese medicine, western medicine, food, health care products, chemical industry products, etc. the advantage of spray drying lies in the investment cost, but the solubility, original flavor and powder shape of the product have obvious defects, It is even more helpless for products with higher viscosity and heat sensitivity requirements. Conventional freeze-drying can obtain excellent product solubility and high-quality products, but the yield is too low and the cost is high.

The process indicators of the MJ series automatic vacuum low-temperature continuous dryer are just between the above two equipment. It can make the inside of the dried product become porous and loose, retain the original properties, and have a good appearance. Vacuum drying condition can meet the processing requirements of most heat-sensitive materials.

The MJ series automatic vacuum low-temperature continuous dryer breaks through the technical problem of continuous feeding and discharging under vacuum, and successfully transforms static drying into dynamic drying. While greatly increasing the output of dry products, it also reduces the production cost.

The MJ series automatic vacuum low-temperature continuous dryer is especially suitable for drying of high-viscosity, high-fat, high-sugar materials, which are difficult for spray dryer and vacuum oven. And it can maintain the stability of the product batch.

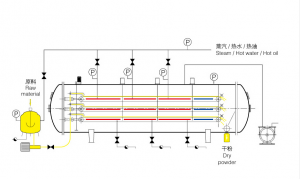

Flow chart of vacuum belt dryer

Main features of MJ vacuum belt dryer:

- Complete automation, pipelineization and continuity

- Realize continuous feeding and discharging under vacuum conditions

- Complete drying, crushing and granulation under vacuum

- The production and operation cost is 1/3 of the vacuum oven and spray drying, and 1/6 of the freeze drying

- Two operators only, greatly reduces labor costs

- The drying temperature can be adjusted according to the material process requirements (25℃~150℃)

- Heat-sensitive materials are non-invariant and non-contaminated

- 30~60 minutes start to produce dry powder continuously, the yield rate of dry powder is 99%

- It can solve the drying of various liquid and solid materials with high viscosity and difficult to dry

- Online automatic cleaning, in line with GMP requirements

With more than 20 years of technology accumulation, Minjie has become the world’s largest manufacturer of vacuum belt drying equipment

The market share of vacuum belt dryer reaches 72%

The market share of ultra-low temperature vacuum concentrator reaches 100%

The few domestic companies in this industry whose annual sales have exceeded 100 million yuan;

Our VBD have been in service for Nestlé, AB Food (British United Food Group), Indonesia PT.MAYORA, Ukraine T.B.Fruit, China Resources Sanjiu Group, Hongri Pharmaceutical, Sunflower Pharmaceutical, Shanghai Pharmaceutical Group, German Doehler Group and other well-known enterprises in various industries in China and abroad.

Various vegetable soups, yeast extract

*Carrot

*Beet

*celery

*onion

*Garlic, tomatoes, condiments

*Beef bone, pork bone, chicken essence

*Instant soup mixture

*Yeast

*Rhubarb

*Various proteins (amino acids)

Juice (fruit) concentrates – non – alcoholic beverages, pastries

* Drinks, pastries, ice cream, cakes

* Materials such as yogurt

* Water juice powder (apple, pear, apricot, orange, grape, lemon, papaya, mango, etc.)

* Berries (grape, strawberry, black rice fruit)

* Pectin

Chemical products

* Synthetic Lysine (L Lysine)

* Anti-biomass

* Powder natural paint

Products containing cocoa and sugar

* Milk powder

* coffee

* High-calorie fruits

* Saccharin

* Low nutritional value

* Sweetener

* Chocolate (cocoa)

Enzymes, vitamins, condensate and intermediate products of beer brewing

* Amylase

* The intermediate product of vitamin base

* Intermediate product of natural vitamin base

* Mixture of natural vitamins

* beer yeast

* Malt extract (maltose, wort)

* Hop Extract

Medicinal plant essences

* Chinese medicine essence

* Aesculus

* Aloe

* Strong agent containing various vitamins

Technical parameters of vacuum belt dryer: