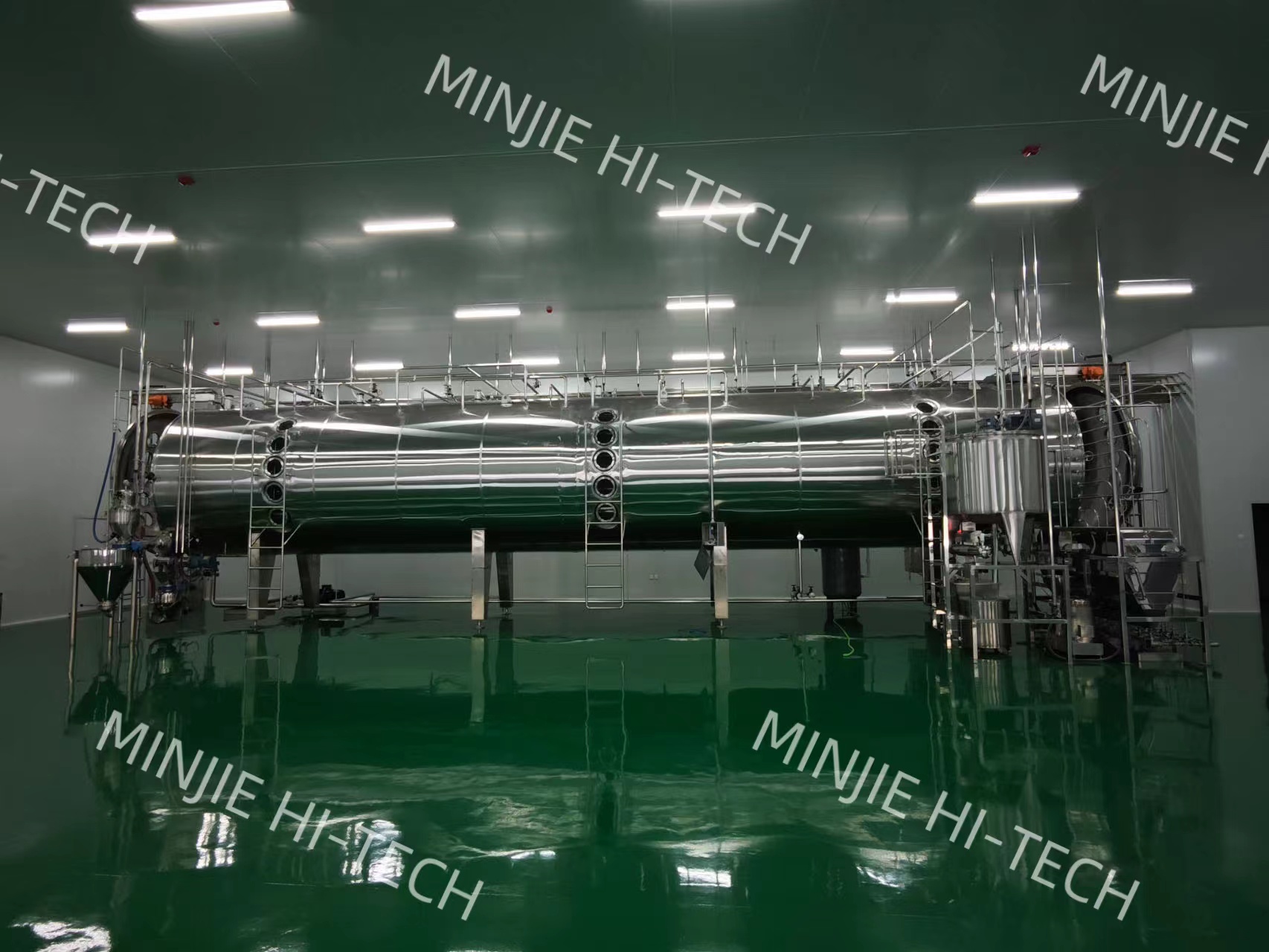

On December 3, two large trucks carrying MJY60-6 vacuum low temperature dryers and MJ-NS-5 ultra-low temperature vacuum thickeners slowly drove out of the Shanghai Minjie Phase I production base and went straight to Quzhou, Zhejiang.

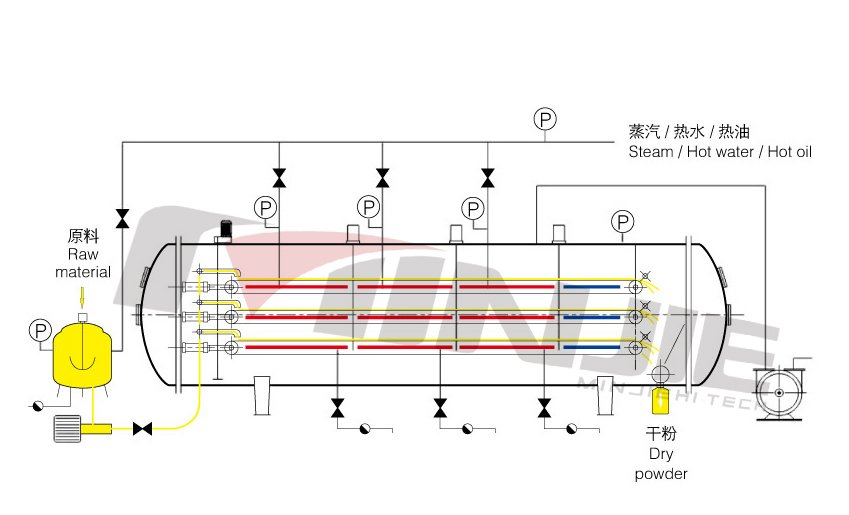

Because the concentrated liquid in this project has a high water content, it is necessary to use an ultra-low temperature vacuum concentrator to concentrate the water content in the concentrated liquid from 90% to about 40%. Then use a vacuum low temperature dryer to dry it and make powder.

The vacuum low-temperature dryer has 6 layers of conveyor belts. The materials are continuously fed through the feed pump and distributor, and then evenly distributed on the conveyor belt under vacuum. After evaporation, drying, cooling, etc., the process is completed. Drying of materials. In this process, the specific temperature can be adjusted according to the characteristics of the material. The discharge end is equipped with a specific vacuum crushing device to reach the finished product of different particle sizes. The dried material can be automatically packed or subsequent processes.

The drying process is automated and continuous, which greatly reduces labor costs, and at the same time, achieves low energy consumption and high product yields.

Created considerable economic benefits for customers.