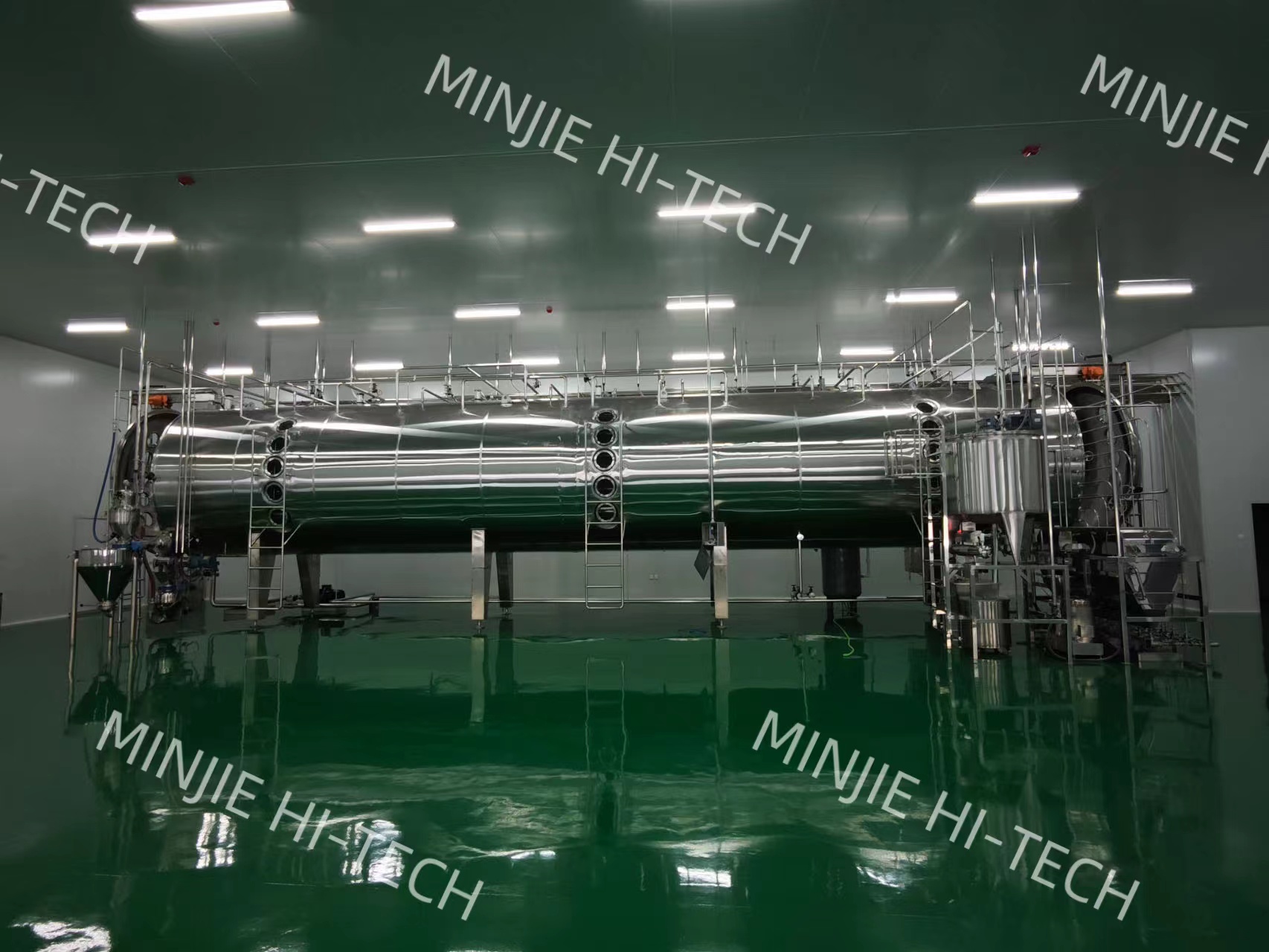

The dehydrated vegetable dryer is a special equipment researched and developed on the basis of the traditional mesh belt dryer. It has strong pertinence, practicability, and high energy efficiency. It is widely used in the dehydration of various regional and seasonal vegetables and fruits. Dry, such as: garlic slices, pumpkin, konjac, white radish, yam, bamboo shoots, etc.

The equipment is long-term tracked by the scientific and technical personnel of Shanghai Minjie Machinery to serve users, and in-depth users to conduct debugging and research, obtain practical data and combine advanced technology to develop and produce. So far, vegetable dehydration dryers have been developed. When the user produces equipment, according to the characteristics of the desired dried product, the user’s process requirements, and the experience accumulated over the years, the most suitable and best quality vegetable drying equipment is designed for the user.

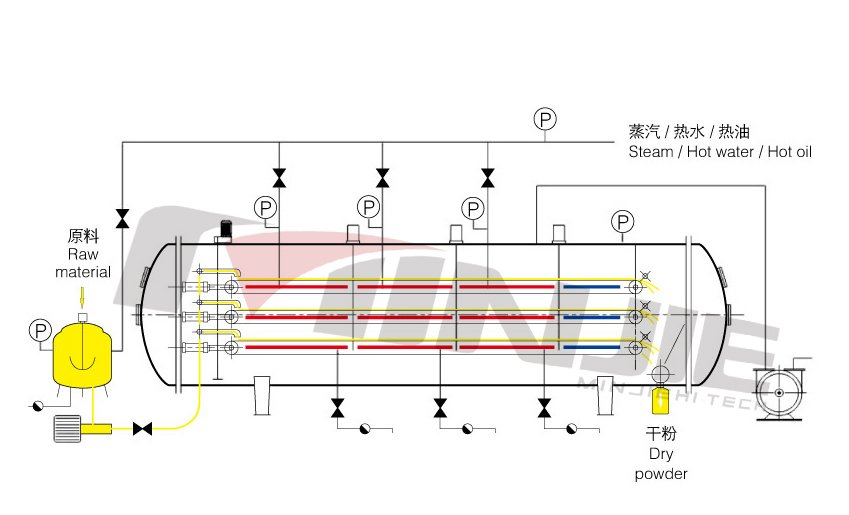

Working principle of dehydrated vegetable dryer

According to the size of the customer’s production capacity, 3-11 layers of conveyor belts are designed and arranged in the vacuum container. Through the continuous solid feeder and the distributor, the raw materials that the customer needs to be dried are continuously fed under the vacuum condition, and they are evenly distributed for drying. With the belt, because the material is constantly turning during the drying process, the evaporation speed and time are accelerated, and the uniformity of the product during the drying process is ensured. The drying temperature is adjustable at 20-150°C. The material enters the dryer and exits after drying. The material is adjustable in about 20-80 minutes. If the dried product needs a crushing process, it can be crushed under vacuum conditions to avoid flying dust, increase product yield and solve problems such as pollution. The dried product is continuously discharged through the vacuum continuous discharger and the vacuum receiver, and at the same time, the organic solvent can be recovered, which solves the environmental protection problem and increases the solvent recovery revenue.

Equipment characteristics of dehydrated vegetable dryer

The drying area, wind pressure, air volume, drying temperature, and mesh belt speed can all be adjusted to suit the characteristics and quality requirements of vegetables. According to the different characteristics of vegetables, different technological water processes and necessary auxiliary equipment can be added. It can meet the drying and mass continuous production of vegetable materials such as roots, stems, leaves, strips, blocks, flakes, and large particles, while retaining the maximum nutrients and colors of the products.

Typical materials for drying are: garlic slices, pumpkin, carrots, konjac, yam, bamboo shoots, horseradish, onions, apples, etc.

The vegetable dehydration dryer is composed of main components such as an inflammator, a drying bed, a heat exchanger and a moisture exhaust fan.

When the dryer is working, the cold air is heated by the heat exchanger, and the scientific and reasonable circulation method is adopted to make the hot air flow through the dried material on the surface for uniform heat and mass exchange. The hot air flow in each unit of the body plays the role of the circulating fan Circulate hot air under low temperature and high humidity at last, and complete the whole drying process smoothly and efficiently.